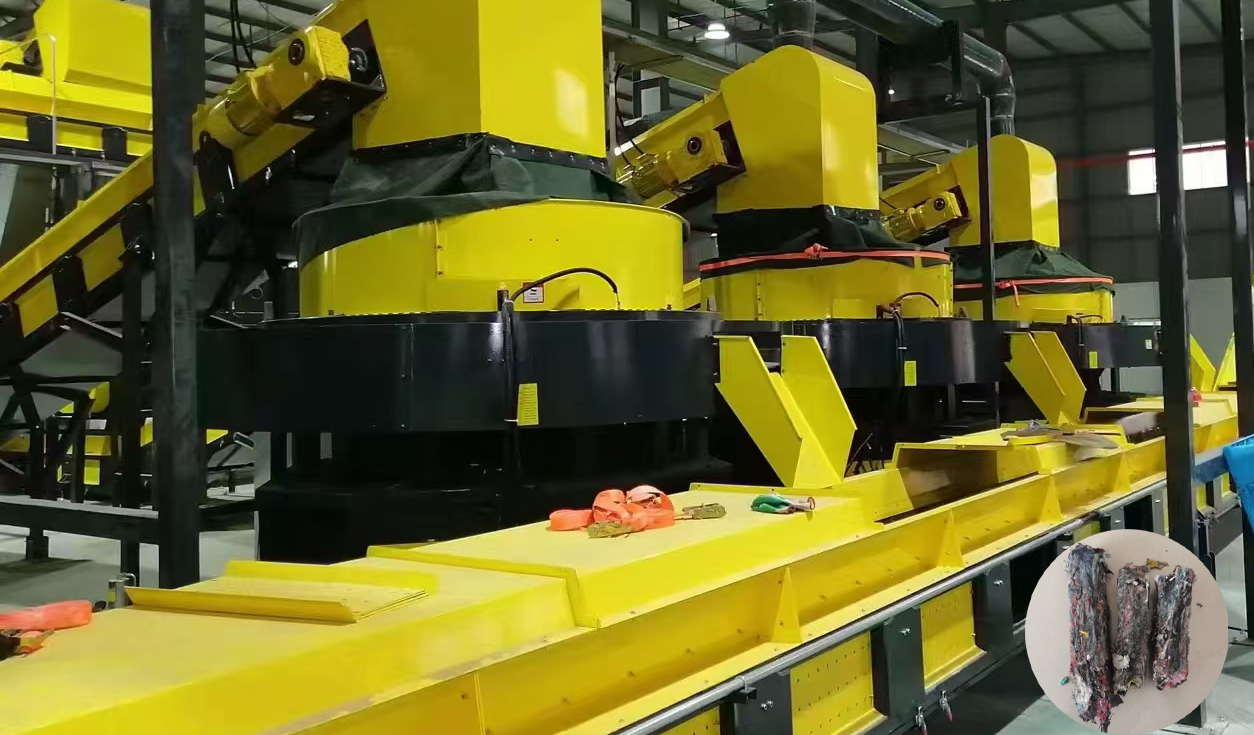

Learn about RDF Pellet Machine : How is RDF fuel rod made?

1.) RDF (Refuse Derived Fuel) fuel rods are extracted and processed from combustible refuse. Below is an overview of the main applications of RDF fuel rods and their advantages:

2.)Application field:

1.Power generation project: RDF fuel rods can be used as fuel for thermal power plants, replacing some coal for power generation.

2.Cement manufacturing: As an auxiliary fuel in the cement production process, replacing some fossil fuels.

3.Heating engineering: Used in central heating systems to provide the required heat energy.

4.Drying engineering: Provides heat in industrial processes that require drying treatment.

5.Industrial boiler: used as a heat source in various industrial production.

3.)Advantage

1.High calorific value: RDF fuel rods have a high calorific value, typically between 14,600 and 21,000 kilojoules per kilogram, which makes them an efficient energy source.

2.Combustion stability: the shape is consistent and uniform, which is conducive to stable combustion and improve combustion efficiency.

3.Environmental protection: chlorine-containing plastics make up only a small proportion, and can be dechlorinated in the furnace by adding lime, thus reducing the emission of pollutants such as chloride gas and dioxins.

4.Operational flexibility: production is convenient, not limited by site and scale, and is usually transported in 500kg bags for easy management.

5.Reuse of resources: When used as fuel, reliance on traditional fossil fuels can be reduced while reducing the need for landfill.

6.The residue disposal is simple: the manufacturing process produces a lower proportion of non-combustible materials (1% to 8%), the residue is also relatively small and cleaner, high in calcium, easy to handle and use.

In general, RDF fuel rods are increasingly being used as a sustainable energy solution in a number of industries. As technology advances and environmental awareness increases, it is expected that the application range of RDF fuel rods will further expand.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...