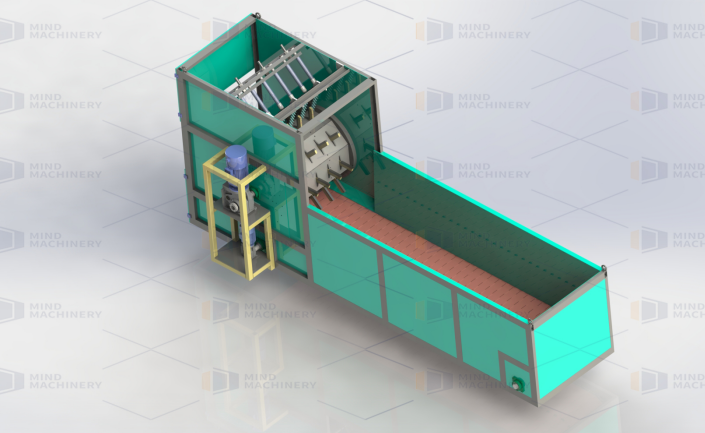

Bag Opener for solid waste sorting system

What is a Bag Opener?

A bag opener is a specialized machine used in waste management to

cut open bags of waste materials automatically. This machine is essential

for facilities dealing with large volumes of bagged waste, as it streamlines

the process of emptying bags, allowing for faster and more efficient sorting

and recycling.

Through the rotating movement between the rotating movable knife and the

fixed knife, use working gap is to ensure that the rotating knife does not collide

with the fixed knife, and the bagged garbage is broken to achieve the effect of

separating the garbage from the plastic bag. When the material is too large,

the force of the fixed knife changes. When the external force is greater than

the spring thrust, the gap between the fixed knife and the movable knife will

increase accordingly to ensure normal work.

Key Features

Bag openers come equipped with several key features designed to handle various types of

bagged waste

Automatic Operation: Reduces the need for manual labor, increasing processing speed and safety.

Versatility: Capable of handling different bag sizes and types, including plastic, paper, and woven bags.

Durable Construction: Built with high-quality materials to withstand harsh operational environments.

Adjustable Settings: Allows customization for different bag types and waste materials to ensure optimal performance.

Applications of Bag Openers

Bag openers are used in various industries to improve waste processing efficiency.

Common applications include

1,Municipal Waste Management: Opening and emptying household waste bags for sorting and recycling.

2,Industrial Waste Processing: Handling large volumes of bagged industrial waste,

such as packaging materials and production scraps.

3,Recycling Facilities: Preparing bagged recyclables for further processing and separation.

4,Composting Operations: Opening bags of organic waste for composting processes.

Safely opening and processing bags of hazardous materials to ensure proper disposal.

Benefits of Using Bag Openers

Implementing bag openers in waste processing operations offers numerous benefits:

Increased Efficiency: Automating the bag opening process speeds up waste handling

and reduces bottlenecks in processing lines.

Labor Cost Savings: Minimizes the need for manual labor, lowering operational costs

and reducing worker fatigue.

Enhanced Safety: Reduces the risk of injuries associated with manual bag opening,

promoting a safer work environment.

Consistent Performance: Ensures uniform opening and emptying of bags, improving

the accuracy and efficiency of downstream sorting processes.

Environmental Impact: Efficient waste processing supports recycling and reduces landfill

usage, contributing to environmental sustainability.

Our Commitment to Innovation

We are committed to advancing waste processing technology to create a more efficient

and sustainable future. Our bag openers are designed with the latest innovations to ensure

high performance and reliability. We offer comprehensive support, from initial consultation

and design to installation and maintenance.

Explore our range of bag openers and discover how they can enhance your waste processing

operations. Contact us today to learn more about our products and services.

| BO12 | BO14 | BO16 | BO18 | |

| Width | 1200mm | 1400mm | 1600mm | 1800mm |

| Number of rotors | Two | Two | Two | Two |

| Speed of the main rotor | 0-25 rpm | 0-25 rpm | 0-25 rpm | 0-25 rpm |

| Speed of second rotor | 0-5 rpm | 0-5 rpm | 0-5 rpm | 0-5 rpm |

| Power | 15+5.5kw | 15+5.5kw | 15+7.5kw | 15+7.5kw |

| Throughput | 10-30m³/h | 20-50m³/h | 40-80m³/h | 60-100m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...

-

2024-05-18C Series Jaw CrusherC series jaw crusher is a jaw crusher with excellent performance introduced and developed by zchmachinery according to the market demand. Compared with traditio...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...