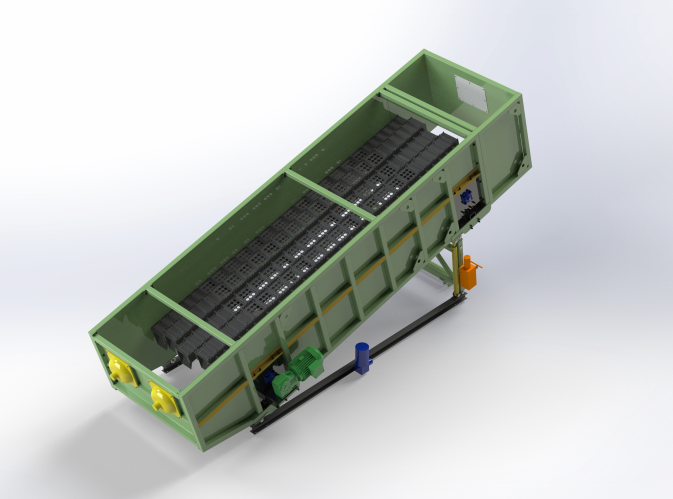

ballistic segregation machine

A ballistic separator, as the name indicates is a high-load segregating device that separates wastes of different kinds.

It consists of parallel agitating paddles and a deck that oscillates at high speed to sort a stream of waste passed through it.

Waste products having similar shapes and sizes are separated from the rest in two or three fractions,

for example, stones, C&D waste (Construction & Demolition waste), glass, and metal substances are

easily separated from reusable paper, plastic, cardboard, and other recyclable products along with RDF

(Refuse Derived Fuel) while the rest minus material is separated.

They can also sort fine particles that can be collected separately with the optional variable screen openings.

In addition to being durable and accurate, with additional features that boost performance.

Types:

The ballistic separators are separated by the quantity of paddles that decide the surface of the

screening and the flow of material processed from the separator.

4 Paddles: the smallest ballistic separator type of ballistic separator. It may be used in small plants

or to improve the efficiency of the collection, in conjunction with an air separator.

8 Paddles: an intermediate variant that can also be supplied with oversized paddles in an edition, to

raise the screening surface while retaining the same number of paddles and to increase the total dimensions

marginally. From the option of cardboard > A4 to the distinction between bottles (3D) and film (2D) in the

plastic flood, the functions that this system can perform are various.

12 Paddles: a model designed to satisfy the specifications of waste sorting plants with large flow rates;

available with regular and oversized paddles; the latter leads to a system with an internal working

diameter of 4300 mm and a screening surface of 24 m2.

16 Paddles: is one of the world's largest ballistic separators. A separator with an internal diameter

of almost 6 meters and a screening area of 32 m2 to satisfy the specifications of systems with

increasing flow rates (50 + t/h sorting lines).

Why should you choose us :

Ballistic separator is the best choice at low cost and with good availability, for an efficient sorting operation.

• Ballistic or Gravity separators are designed to separate biodegradable and non-biodegradable waste solids.

• By adjusting the rotational speed, the conveying speed, the ballistic separation and the degree of material mixing can be modified.

• A separation accuracy of 90% can be obtained.

Efficient Sorting Operation:

The Ballistic Separator Machine is the high load segregation device that segregates waste of different types based on their size and weight such as:

• Construction & Demolition Waste (C&D)

• Stones

• Fibers

• Wood

• Glass

• Metal

• Rubber

• Plastic

Paper

• Containers

• Cans

• Cardboards

• Other recyclable products

Parameters sheet :

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 4 - 6 | 6 - 8 | 6 - 8 | 6 - 10 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° |

| Sieve hole size | 20-80 mm | 30-80 mm | 30-80 mm | 30-80 mm | 30-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2- 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw - 15kw | 11kw -18.5kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2024-08-07Tire double shaft shredderOperation:Feeding: Whole or pre-cut tires are fed into the shredder through an inlet hopper.Shredding: As the tires enter the shredding chamber, the rotating cu...