Why choose ballistic separator for a small scale waste sorting project

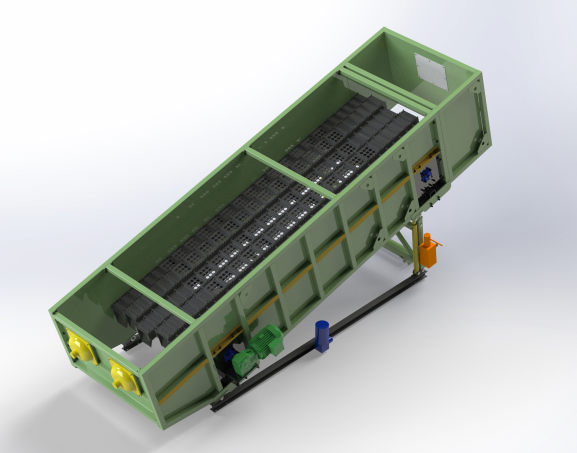

A ballistic separator is a type of equipment used in municipal solid waste (MSW)

sorting lines to separate materials based on their size, shape, and density.

It works by using a combination of vibration and air pressure to separate

lightweight materials from heavier ones.

Product Highlights

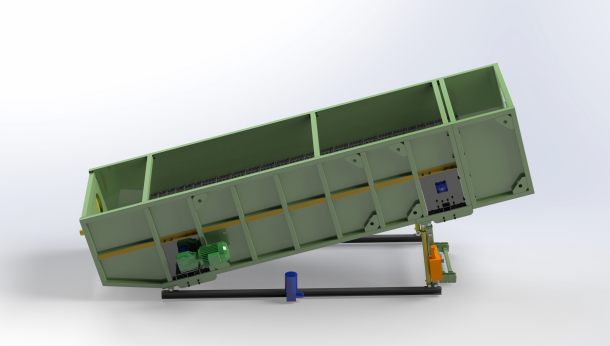

1,Different lengths and working widths for different throughput capacities;

2,Three machine types for three special types of application;

3,Unique straight shafts with individually exchangeable eccentric bearings;

4,Exchangeable screen grid plates on the paddles.

High Precision

The conveying speed, the ballistic separation and the level of material mixing

can be adjusted by modifying the rotational speed. A separation precision of

up to 90% can thus be achieved.

How Does a Ballistic Separator Work?

It separates the material into three fractions.

Separation takes place in just one step.

The fed material is conveyed both vertically and horizontally on the paddles.

The vertical acceleration mixes the material thoroughly,

resulting in good separation and a high separation quality.

Parameter Sheets

| BS04 | BS06 | BS08 | BS10 | BS12 | |

| Paddy Number | 4 | 4 - 6 | 6 - 8 | 6 - 8 | 6 - 10 |

| Paddle length | 5.5m | 5.5m | 5.5m | 5.5m | 5.5m |

| Angle adjustment | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° | 0 – 25° |

| Sieve hole size | 20-80 mm | 30-80 mm | 30-80 mm | 30-80 mm | 30-80 mm |

| Fan Number | 2 - 4 | 2 - 4 | 2- 4 | 2 - 4 | 2 - 4 |

| Power | 5.5kw | 7.5kw | 11kw - 15kw | 11kw -18.5kw | 22kw |

| Throughput | 0-30 m³/h | 30-50 m³/h | 50-70 m³/h | 70-90 m³/h | 90-120 m³/h |

Good reason for why choose ballistic separator

1. Efficiency in Separation:

Ballistic separators effectively separate lightweight materials from heavier ones, improving sorting accuracy.

This is particularly beneficial in small-scale operations where maximizing recovery is essential.

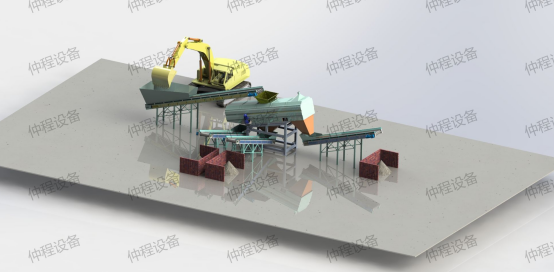

2. Space-Saving Design:

Many ballistic separators have a compact footprint, making them ideal for smaller facilities where space is limited.

They can fit into existing layouts without requiring extensive modifications.

3. Cost-Effective:

For small-scale projects, investing in a ballistic separator can yield high returns by increasing the quality and quantity of recyclable materials recovered.

This can lead to cost savings in waste disposal and increased revenue from selling recyclables.

4. Versatility:

Ballistic separators can handle various types of materials, including plastics, paper, and textiles,

making them suitable for diverse waste streams often found in small-scale operations.

5. Reduced Labor Costs:

By automating part of the sorting process, ballistic separators can reduce the need for manual sorting,

leading to lower labor costs and increased efficiency.

6. Minimized Contamination:

Effective separation helps reduce contamination rates in recyclable materials,

leading to higher-quality outputs and better marketability of recyclables.

7. Easy Integration:

Ballistic separators can be easily integrated into existing sorting lines,

allowing for a straightforward upgrade of current operations without a complete overhaul.

8. Sustainability:

Utilizing a ballistic separator can enhance the sustainability of a small-scale project by improving recycling rates and reducing the volume of waste sent to landfills.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2023-01-12Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...