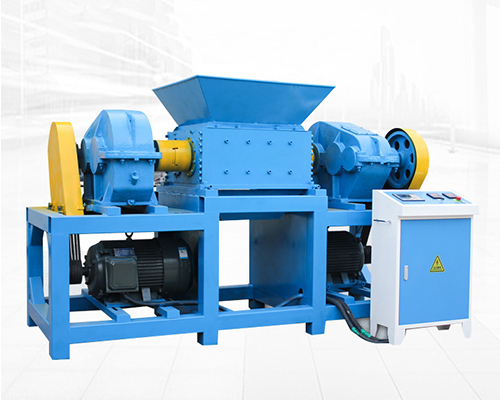

Shear-type shredder

Double-shaft shredder, also known as shear-type shredder, reduces the size of materials by shearing, tearing and squeezing. This shredder is mainly used for the

crushing and recycling of plastics such as strapping tape, tires, films, woven bags, and waste fishing nets. It adopts double-shaft independent drive, unique knife

shaft structure and four-corner rotating cutter. In the production process of low speed and high torque, there will be no entanglement or jamming of the

equipment, thereby improving production efficiency.

Equipment features:

Heavy moving knife, high crushing efficiency. Both the moving knife and the fixed knife are cast with alloy steel, which is strong and has a long service life.

The iron frame plate is thick, can resist high torque, and is very strong.

Easy to adjust, low maintenance cost, economical and durable.

The unit output is the theoretical calculated throughput. The specific use should be based on the actual density and shape of the crushed object.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-04-25Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...