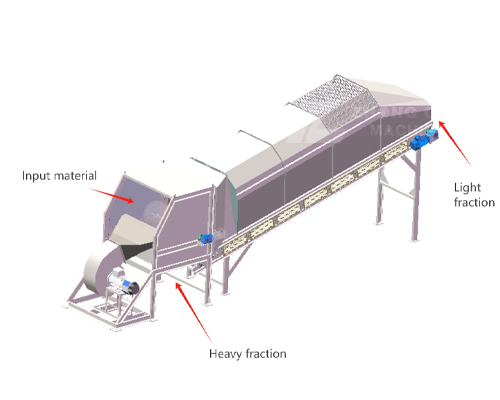

Equipment for separation of light and heavy materials--Windshifter

1). Introduction

Windshifter is also called windshifter, air drum separator and air classifier etc..

The Windshifter machine in the garbage sorting equipment is a device specially used for garbage sorting and processing. It uses airflow to separate waste of different densities or sizes. This type of equipment plays an important role in improving resource recovery and reducing environmental pollution. The following will introduce its working principle, advantages and application areas in detail.

2). Working principle

1. Material feeding: First, the garbage to be processed is fed into the Windshifter machine through a conveyor belt or other means.

2. Pretreatment (if necessary): Sometimes, before entering the main sorting process, it may be screened and other steps to remove oversized objects or perform preliminary classification.

3. Separation under airflow: Inside the machine, strong airflow blows the material upward. Because the density of garbage of different materials is different, under the same conditions, light objects will be carried away by the airflow and discharged from the top; while heavy objects will remain below and continue to move forward or fall directly.

4. Collection and discharge: Depending on the design, light materials may be transported to a designated location for collection through a pipe; while heavy materials are usually removed by sliding out along the bottom or being grabbed by other robotic arms.

3). Advantages of air classifier:

1. High sorting efficiency: It can quickly separate light and heavy materials in garbage, with a large processing capacity, which can meet the needs of large-scale garbage treatment. For example, in large garbage treatment plants, air classifiers can efficiently sort a large amount of garbage and improve processing efficiency.

2. Simple operation and maintenance: It is easy to operate. Just put the garbage into the equipment and turn on the power to achieve automatic sorting. And the maintenance of the equipment is relatively easy. You only need to regularly clean the dust and debris inside the equipment to keep the equipment running normally, reducing maintenance costs and labor intensity

3. Wide range of applications: It can handle various types of garbage, including urban domestic garbage, construction garbage, stale garbage, industrial garbage, etc.

4. High sorting purity: Based on the principle of aerodynamics, it can accurately separate light materials, ensure the high purity of recycled aggregates, etc., which is conducive to subsequent resource recycling.

5. Good environmental protection: No dust will be generated during the work process, avoiding harm to the environment and human health, and no secondary pollution will be generated, which meets environmental protection requirements.

6. Energy saving and low consumption: The operating cost is relatively low. Compared with some complex garbage sorting equipment, the Windshifter has lower energy consumption.

4). Application areas

1. Urban domestic waste treatment: Help to achieve effective separation of recyclable items such as paper and plastic bottles from other non-recyclable items.

2. Industrial waste management: Applicable to the treatment of solid waste generated in various production processes.

3. Building demolition site cleaning: It can be used to select valuable building materials such as wood and metal.

4. Agricultural waste recycling: For example, select the part that can be used for biomass energy production from crop residues.

5). In summary, the air classifier plays an irreplaceable role in promoting resource recycling with its unique advantages. With the advancement and development of technology, such equipment will have broader application prospects in the future.

| Windshifter800 | Windshifter1200 | Windshifter1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...

-

2024-04-25Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...

-

2024-05-18C Series Jaw CrusherC series jaw crusher is a jaw crusher with excellent performance introduced and developed by zchmachinery according to the market demand. Compared with traditio...