Bouncing screen: an industrial solution for efficient particle separation

Introduction to Bouncing Screen:

A bouncing screen is a type of screening equipment used for separating particles of different sizes. It mimics the action of manually tossing and sieving materials by using elastic vibrations to make the material bounce on the screen surface, thereby achieving grading, impurity removal, and other purposes.

Working Principle:

The working principle of a bouncing screen relies on its unique vibration mechanism. The machine generates vertical oscillations that cause the material layer on the screen to jump up and down. This motion allows smaller particles to pass through the screen openings while larger particles remain on top, thus achieving effective separation based on particle size.

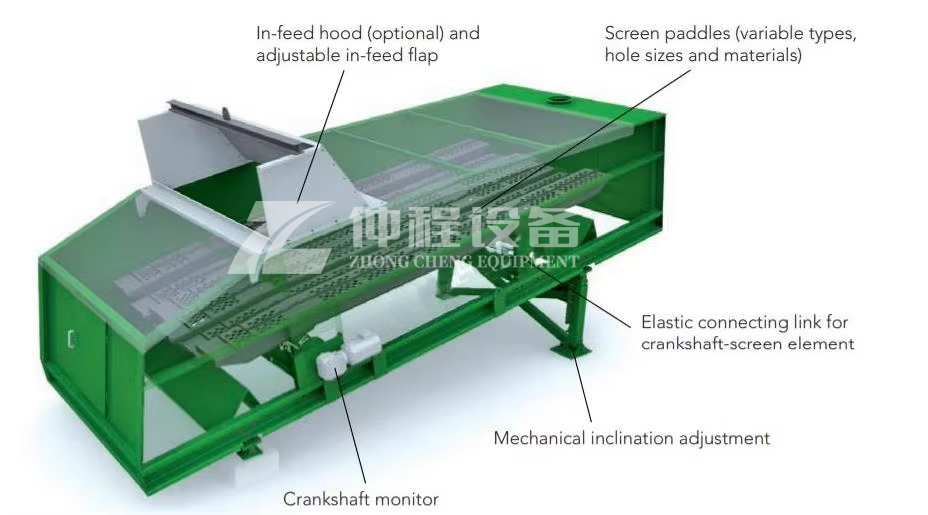

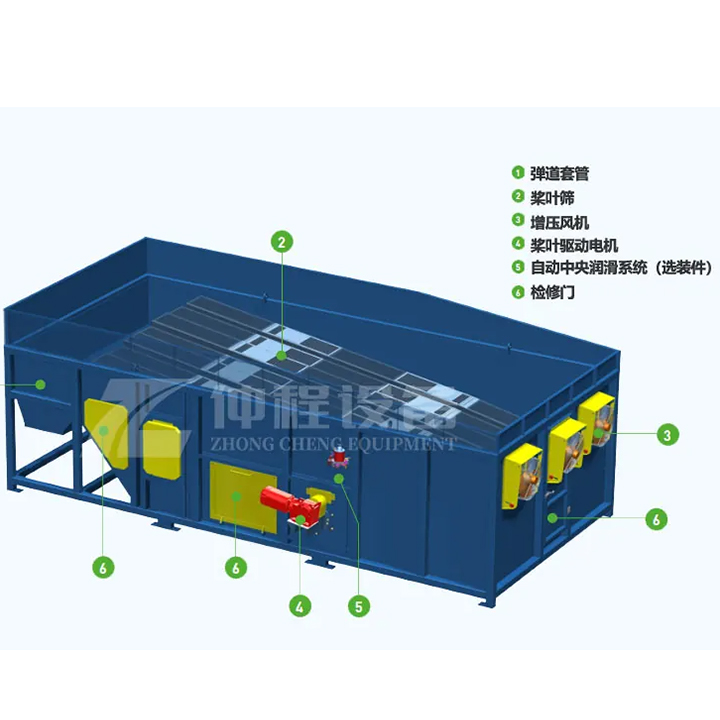

Structure:

- Screen Surface: Typically made of wire mesh or perforated plates with specific aperture sizes.

- Vibration Generator: Can be an eccentric motor or other types of vibration exciter that creates the necessary oscillating motion.

- Support Frame: Provides structural support and houses the vibration generator.

- Elastic Elements: Springs or rubber blocks that enable the screen to bounce.

Material Inlet and Outlet: Designed for feeding material into the system and discharging it after processing.

Applications:

Bouncing screens are widely used in various industries such as agriculture, food processing, recycling, mining, and chemical processing. They are particularly useful for separating grains, seeds, plastic pellets, crushed minerals, and other granular materials.

Specifications:

| Model | Dimension(mm) | power(kw) | Capacity(t/h) |

| 1240 | 1.2m*4m | 5.5kw | 30 |

| 2060 | 2m*6m | 15kw | 150 |

Advantages:

- Efficiency: High efficiency in separating materials of different sizes.

- Low Maintenance: Simple structure with fewer moving parts, reducing maintenance needs.

- Energy Saving: Lower energy consumption compared to some other types of screening equipment.

- Versatility: Can handle a wide range of materials and particle sizes.

- Gentle Handling: Minimizes damage to delicate materials during the screening process.

Main Function:

The main function of a bouncing screen is to separate mixed materials into different grades according to their size. This is crucial for ensuring product quality in manufacturing processes, optimizing resource utilization, and preparing materials for further processing or packaging.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...