Clean Source Rod Keeper-RDF Rod Making Machine

RDF rod making machine is a kind of equipment that processes various wastes into high-density rod-shaped solid fuels. The following is a detailed introduction to it:

1). Main functions and uses

1. Energy regeneration: Process agricultural and forestry processing wastes such as wood chips, straw, rice husks, bark and other biomass, as well as the combustible parts of domestic garbage and industrial solid waste, such as plastics, paper, leather, cloth strips, etc. into RDF fuel rods to realize the energy utilization of wastes, turn waste into treasure, and effectively alleviate the problem of energy shortage.

2. Fuel supply: The manufactured RDF fuel rods have the characteristics of high calorific value, flammability, and low ash content. They can replace traditional fuels such as firewood, raw coal, and gas. They are widely used in heating, domestic stoves, boilers, biomass power plants, cement plants and other places to provide them with a stable fuel supply.

2). Working principle

1. Raw material pretreatment: First, the raw materials are pretreated by crushing and drying to meet certain particle size and moisture content requirements. Generally, the length of the raw material is required to be less than 50mm, and the moisture content is controlled within the range of 10%-25%.

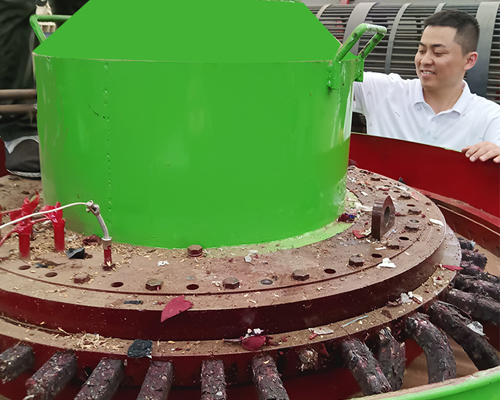

2. Mechanical extrusion molding: The pre-treated raw material is fed into the feed port of the rod making machine, and the rotation of the main shaft drives the roller to rotate. The centrifugal force generated by the roller forces the raw material into the mold hole. The raw material is subjected to high pressure in the mold hole and is compressed into a rod-shaped solid fuel, and finally falls from the discharge port.

3). RDF rod making machine has many advantages, the following is a detailed introduction:

1. Significant energy regeneration and environmental protection benefits: RDF The rod making machine can convert the combustible parts of agricultural and forestry processing waste, domestic garbage and industrial solid waste into high-density rod-shaped solid fuel, realize the energy utilization of waste, effectively reduce the amount of landfill and pollution to the environment, and comply with national environmental protection policies and sustainable development requirements.

2. Wide adaptability of raw materials: It can process a variety of raw materials, such as wood chips, straw, rice husks, bark and other agricultural and forestry biomass, as well as plastics, paper, leather, cloth strips and other domestic garbage and industrial solid waste combustible materials, making full use of various waste resources and expanding the range of raw material sources.

3. Good molding effect: Through the reasonable design of the structure of the pressure roller and the mold, and the precise control of parameters such as pressure and temperature, the RDF fuel rods are tightly molded, smooth in surface, uniform in density, with high strength and stability, not easy to break and loose, and improve the quality and combustion performance of the fuel rods.

4. High production efficiency: It adopts advanced transmission system and molding technology, with high production efficiency, and can produce a large number of RDF in a short time. Fuel rods, meet market demand and improve production efficiency.

5. Low energy consumption: The equipment consumes relatively low energy during operation, which can effectively reduce production costs and improve economic benefits, and also meet the requirements of energy conservation and emission reduction.

6. High equipment stability: The overall structure is reasonably designed, and key components are made of high-quality materials. After strict quality inspection and debugging, the equipment operates stably and reliably, with low failure rate and long service life, and can meet the requirements of long-term continuous operation.

4). Specification

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.