Double-shaft shredder characteristics

The commonly used double-shaft shredder is a shearing shredder. The double-shaft shearing shredder uses the working principle of mutual shearing, tearing and squeezing between the knives to process the materials. It has a good crushing effect on soft and hard materials and is often used in environmental protection fields such as MSW (municipal domestic waste) disposal, resource recycling, and waste incineration pretreatment. The equipment adopts a low-speed, high-torque design with the characteristics of large shear force, good shredding effect, low noise, and good stability. GEP Environmental Protection is also good at system optimization and intelligent detection. It has professional process design engineers to provide system layout and equipment selection, real-time monitoring of equipment operation status and data, and predicting equipment failures in advance, reducing the maintenance and repair costs of equipment failures, and ensuring the continuous and efficient operation of the equipment.

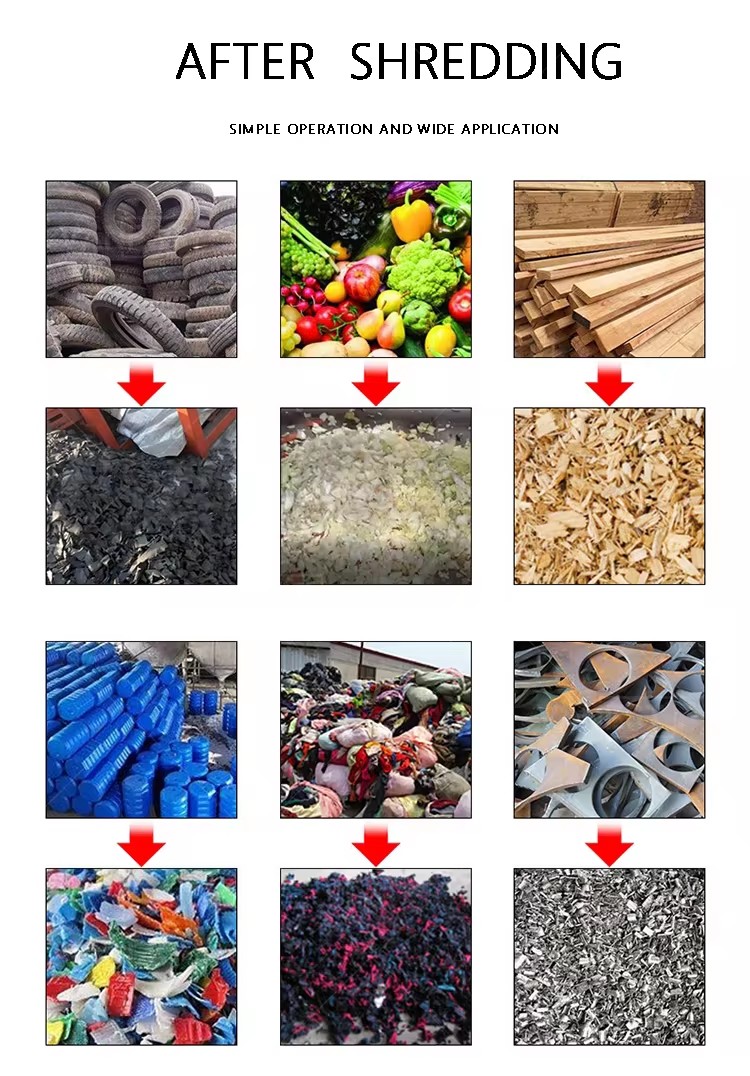

Applicable materials

Household garbage, large garbage, medical waste, hazardous waste, industrial waste, electronic waste, paper mill waste, waste tires, waste fabrics, biomass, organic waste, metal materials, animal carcasses and other solid wastes.

Working principle

The motor drives the two knife shafts to drive the moving knife and the spacer to rotate at a low speed. The adjacent blade edges of the moving knife on the knife shaft form shearing, the tip of the moving knife and the cylindrical surface of the spacer form shearing, and the torsion and speed difference of the knife shaft form tearing to achieve the crushing effect.

Performance characteristics

1. Integral knife box

Guarantees high mechanical strength and processing accuracy, extends the service life of the equipment, and saves operating costs.

2. Independent detachable technology of fixed knife

Each fixed knife can be disassembled and installed independently, and can be disassembled quickly in a short time, which greatly reduces downtime and improves production continuity.

3. Intelligent technology

Adopting intelligent technology, automatic lubrication, intelligent monitoring, abnormal alarm, and design of intelligent protection system for unbreakable objects reduce the risk of failure, ensure the long-term healthy operation of the equipment, and reduce the number of labor and operating costs.

4. Unique anti-loosening technology

Using unique anti-loosening technology, equipment failure caused by loose bolts is avoided.

5. European imported tools with long service life

The raw materials of the tools are imported and processed by special processes, with long service life and good interchangeability.

6. The spindle has good fatigue and impact resistance

The spindle is made of special materials, and has undergone multiple heat treatments and high-precision processing. It has good mechanical strength, strong fatigue and impact resistance and long service life.

7. Imported bearings and multiple combined seals

High load resistance, long life, dustproof, waterproof and anti-fouling, ensuring continuous and stable operation of the machine.

8. PLC touch screen control cabinet

Adopt PLC touch screen control cabinet, equipped with high-end electrical components, good stability and easy operation.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2024-08-16Crop straw double shaft shredderApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...