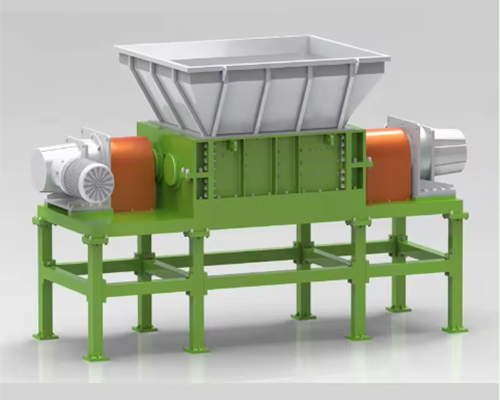

Double-shaft shredder for landfill waste

The double-shaft shredder is a mechanical device specially designed for processing various solid wastes, especially for processing materials with large volume and high hardness. When processing landfill garbage, the double-shaft shredder can play an important role.

Working principle of double-shaft shredder

The double-shaft shredder has two relatively rotating knife shafts, each of which is equipped with multiple blades. When the landfill garbage enters the machine, the blades on the two knife shafts interlace and shear and pull the materials, tearing large pieces of garbage into smaller pieces. This design enables the double-shaft shredder to effectively process mixed waste, including plastics, wood, rubber, fabrics, electronic waste, etc.

Advantages of processing landfill garbage

Reduce volume: Through the processing of the shredder, the volume of garbage can be greatly reduced, thereby saving landfill space.

Improve resource recovery rate: Smaller fragments are easier to carry out subsequent sorting and recycling, which helps to improve the separation efficiency of recyclable materials.

Improve landfill management: The pre-treated garbage is more uniform, which helps to improve the operation and management of the landfill, such as reducing the difficulty of garbage compaction, optimizing leachate management and controlling landfill gas emissions.

Environmental protection: Effective pretreatment can reduce environmental pollution, such as reducing the risk of surface water and groundwater pollution caused by large garbage.

Application Notes

Before using a double-shaft shredder to treat landfill garbage, the garbage should be preliminarily screened to remove large items or hazardous waste that are not suitable for mechanical processing.

Regularly maintain and inspect the equipment to ensure its normal operation and extend its service life.

Pay attention to operational safety to prevent accidents, especially when handling garbage containing metal or other hard materials.

In summary, the double-shaft shredder is an effective means of treating landfill garbage. It not only helps to reduce garbage, but also facilitates resource recycling, and has positive significance for environmental protection.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...