The ZhongCheng Air Drum Separators

The ZhongCheng Air Drum Separators

The Drum Separators are used in the recycling industrie to split/separated a waste flow in 2 waste streams.

A heavy and a light fraction.

Applications

The Air Drum Separator`s are used in the recyclingindustry to split/separate a waste flow in 2 waste streams.

A heavy and a light fraction.

Designs/Specifications

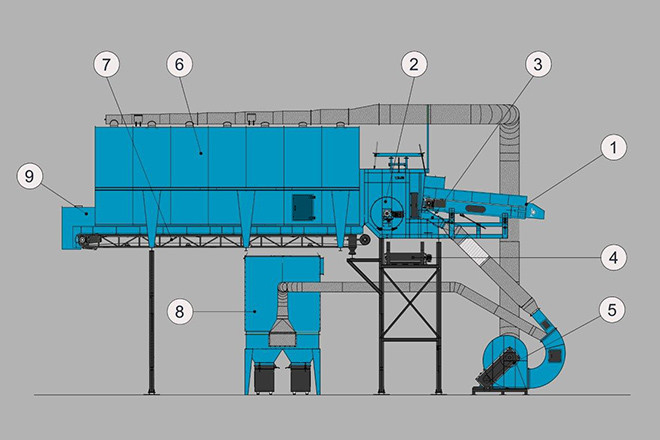

1. speedupband

2. roterende drum

3. blaasmond

4. afvoerband zware fractie

5. ventilator scheider

6. expansiekamer

7. afvoerband expansiekamer

8. stoffilter

9. ontstoffing expansiekamer

Working of the Air Drum Separators

Behind the input conveyor a special speed-up conveyor is placed, which transports the input

fraction into the Drum Separator (1).

You have to take care of a frequency regulator, to regulate the speed of the conveyor between

80 – 120 mtr/min.

The conveyor is adjustable in a horizontal and vertical position and in an angle. Below the

conveyor a blow mouth (3) is installed. The blow mouth is also adjustable in a horizontal and

vertical position and in an angle. To adjust the air flow, the blow mouth is executed with 2 air

regulation valves. Behind the charge conveyor an expansion room with a rotating drum (2)

with a diameter of 1000 mm. is installed.

In the expansion room, using the blowing capacity of the blow mouth and the suction capacity

above the separating drum, the heavy and the lighter fraction will be separated.

Both the inlet, as the distance to the drum till the discharge chute to the expansion room (6),

can be adjusted in height.

Along the front of the drum, the heavy fraction is, by means of a chute, discharged to a discharge

conveyor (4). The discharge conveyor is not part of our delivery.

The lighter fraction is blown over the separation drum and extracted and discharged to the

expansion room (6).

In this expansion room the air is separated from the material.

Below the sedimentation room a discharge conveyor is installed. (7)

To create a suction flow above both the separation drum, the expansion room is executed with

internal boxes which are, by means of 2 suction ducts, connected to one fan separator (5). The

fan will suck for 100% at the sedimentation room.

In the fans the air is separated in an air dust flow of approx. 20% and a blow air flow of approx.

80% and is used to blow the fraction against and over the separation drum.

The air dust flow (20%), containing the dust, is discharged to a dust filter (8).

The fan separator (5) is executed with two regulation valves. These valves determine the amount

of air to the blow mouth (3) and the amount of air which must be discharged to the dust filter (8).

Using these possibilities and the possibilities to adjust the speed-up conveyor of the drum separator

horizontal and vertical and in an angle, it is possible to adjust the unit to the necessary input flows

and fraction sizes.

The special fan separators (5) allow the installation of a relative small dust filter, due to the circulation

of mostly the biggest part of the air.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2024-07-12Crush to Create: The Ultimate Eco-Friendly Plastic Shredder RevolutionThe working principle of a plastic shredder is mainly to tear large plastic materials into small pieces or fragments through mechanical force, in order to facil...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.