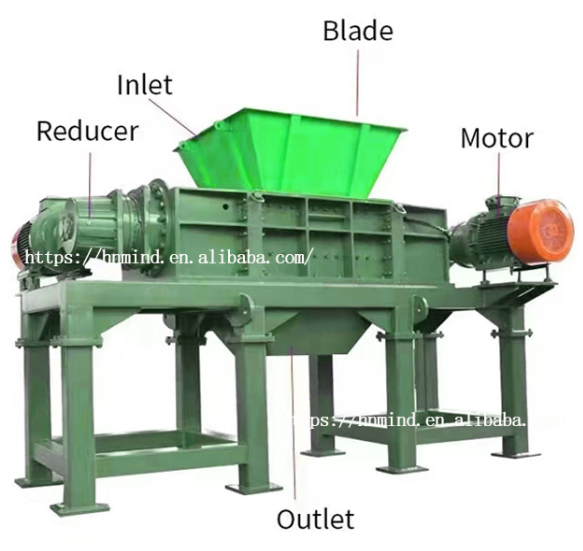

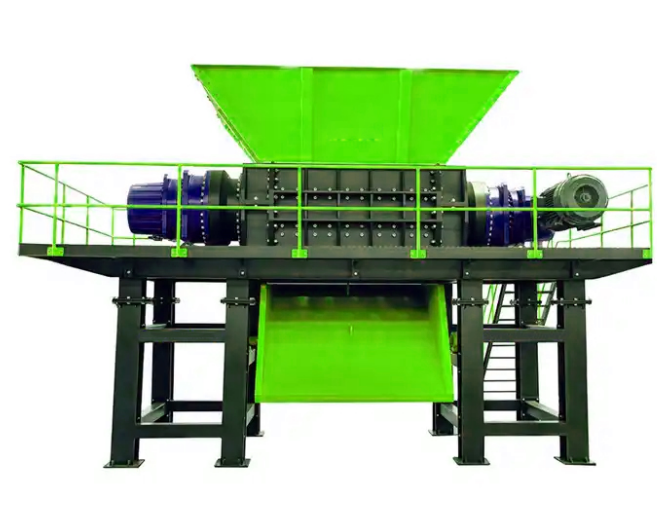

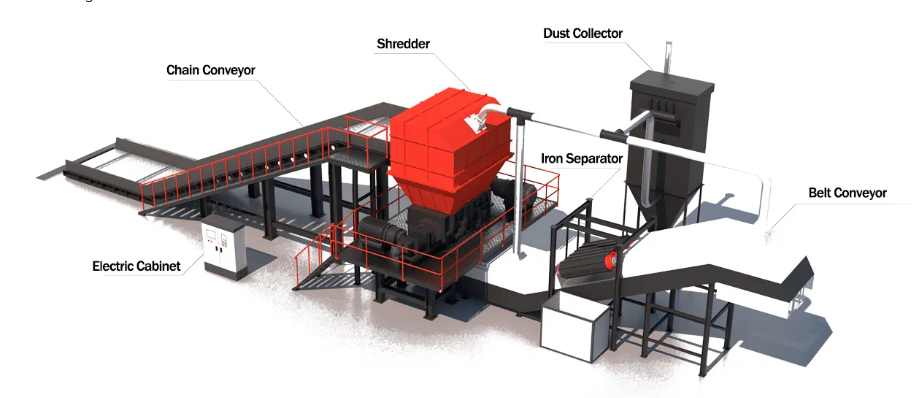

Double Shaft Shredder

Double shaft shredder is designed for a wide array of applications and industries, suitable for shredding

solid material such as E-waste, metal, wood, plastic, scrap tires, packaging barrel, pallets, etc.

Application

Industrial shredder machines have a wide range of applications. Here are some applications of industrial shredders:

1. Waste processing and recycling: Industrial shredders are used for processing and recycling various types of waste,

including paper, cardboard, plastic, metal, rubber, wood, etc. Shredding waste reduces its volume and facilitates

further processing and recycling.

2. E-waste processing: Industrial shredders are specifically designed for processing electronic waste, such as

electronic devices, cables, circuit boards, etc. Shredding e-waste ensures secure destruction of sensitive information

and allows for the recovery of valuable metals and other materials.

3. Automotive recycling: Industrial shredders are used in the automotive recycling industry for the processing

of end-of-life vehicles. They shred car parts and metal scraps for recycling purposes.

4. Plastic processing: Industrial shredders are employed in the plastic processing industry for shredding waste

plastic products, plastic molds, pipes, etc., enabling further processing or recycling.

5. Paper manufacturing and printing industry: Industrial shredders are used for waste paper handling in paper

manufacturing and printing industries. Shredding waste paper reduces costs in pulp preparation and promotes

efficient resource utilization.

6. Medical waste disposal: Industrial shredders are utilized for the disposal of medical waste, including medical

papers, syringes, medical packaging, etc. Shredding medical waste reduces its volume and prevents the leakage

of sensitive information.

7. Metal recycling: Industrial shredders are used for shredding scrap metal products, metal sheets, iron waste, etc.,

facilitating metal recycling and reuse.

8. Plastic bottle and container recycling: Industrial shredders are widely used in the recycling process of plastic

bottles and containers. Shredding waste plastic bottles and containers facilitates storage, transportation, and

subsequent recycling.

9. Wood processing and paper industry: Industrial shredders are utilized in the wood processing industry and

paper industry for the shredding of waste wood and cardboard. Shredding waste wood and cardboard reduces

volume, lowers costs, and promotes resource efficiency.

The double shaft shredders (also called dual shaft shredder) are used for shredding the following materials:

Metal: aluminum can bundle, steel drum, car shell, color steel tile, bicycle, copper aluminum radiator, oil filter,

scrap wires, cables, aluminum composite plastic panel, steel wire rope, gas tank, zip-top can, engine case, paint bucket, etc.

Plastic: plastic pallet, plastic drum, plastic bucket, plastic film, waste appliances shell, garbage plastic drum,

IBC drum, IBC barrel,garbage bag, rubbish bag, plastic pipe, washing machine, forklift pallet, lead acid

battery shell, etc.

Textile: scrap clothes, shoes, fishing net, woven bag, ton bag, jumbo bag, fishing net bundles, dust collector

bag, industrial textile waste, etc.

Wood: wood furniture, wood pallet, scrap timber, sawdust chipboard, composite board, wooden door, forklift

pallet, wood board, wood template, wooden case, etc.

Paper: scrap paper and cartons, including scrap books, carton board, carton box, packaging box, waste

newspaper, office paper, printing paper, paperboard, etc.

Waste household appliances: TV, washing machine, refrigerator shell etc.

Pipes: large pipes, pipe fittings, PE pipes etc.

Scrap tires: car tires, truck tires etc.

All kinds of kitchen waste, domestic waste, rdf derivatives, medical waste,garden waste etc.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

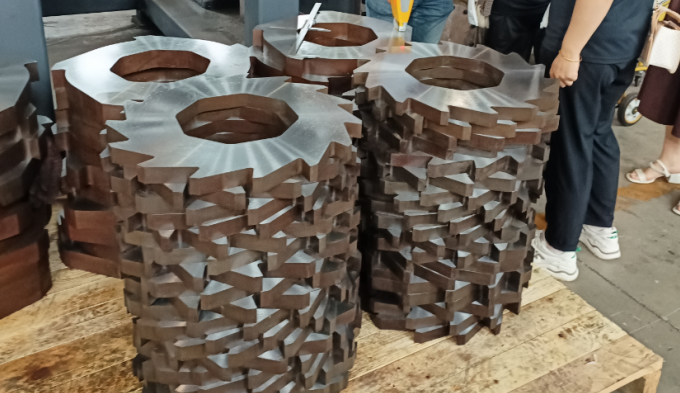

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

Features of double shaft shredder

1,Low speed operation, low noise and less dust.

2,Programmable control, multi-stage speed regulation is suitable for crushing and processing of different materials.

3,The output particles are uniform in size.

4,Robust and rugged machines that have throughput up to 20 tons/hr.

5,Lower power requirements and higher reliability.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2024-08-07Tire double shaft shredderOperation:Feeding: Whole or pre-cut tires are fed into the shredder through an inlet hopper.Shredding: As the tires enter the shredding chamber, the rotating cu...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...