Double-shaft shredder overview

Double-shaft shredder overview

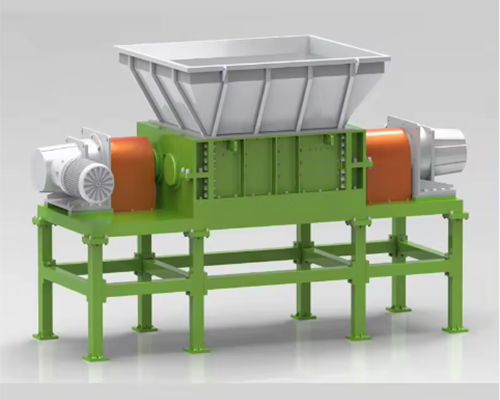

The highlights of Zhengzhou Zhongcheng double-shaft shredder are the stable chassis structure, larger crushing box and easier feeding hopper, higher output

torque and stronger crushing capacity. The equipment is widely used to shred high-hardness, large-volume materials or bundled materials (which may contain

foreign matter. Since the equipment does not contain a screen, it is often used as the primary crushing of raw materials. The size of the crushed particles depends on the width of the blade.

Double-shaft shredder structure

A: Hopper: Customize the hopper size according to customer requirements; Knife roller: Made of high-alloy 42CrMo material, high strength and good toughness;

B: Bearing: Strong and durable;

C: Drive device: Electric drive and hydraulic drive are available;

D: Reducer: Output torque large planetary reducer

E: Control system: Siemens PLC, Schneider Electric original, automatic overload protection, automatic reversal.

Double-shaft shredder blade

Shredder blade is one of the important accessories on the shredder. The quality of the shredder blade directly affects the processing cycle of the machine for

waste. According to the classification of shredders, shredder blades are divided into single-shaft shredder blades and multi-shaft shredder blades. As an important shredder blade. According to the classification of shredder structure, shredder blades can be divided into single-shaft shredder blades and multi-shaft shredder blades.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...