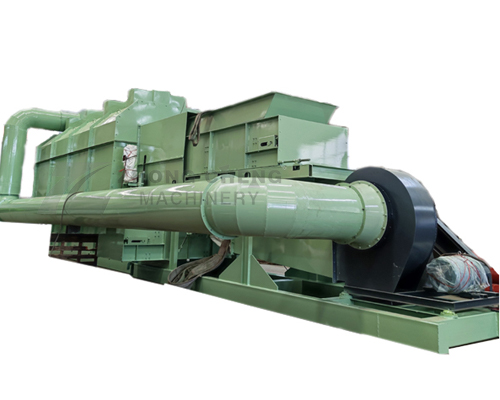

The Detailed Introduction of Garbage Air Drum Separator

1). Working principle

1. Using aerodynamics: The garbage air drum separator mainly uses the principle of aerodynamics to separate light and heavy materials. When the material is fed into the sorter by the feeding equipment, the airflow generated by the fan will blow the material away and suspend it in the air. Since light and heavy materials have different densities, their suspension speeds in the airflow are also different, thus achieving separation.

2. Specific separation process: Light materials such as plastic film, paper, hair, etc. will be blown to a higher position under the action of the airflow, and will be transported to the light material collection device, such as the cyclone dust collector, etc., with the airflow, and finally enter the discharge hopper; while heavy materials cannot be blown up by the airflow or can only be blown up for a short distance due to the large gravity effect, and will directly fall from the heavy material discharge port and enter the next sorting equipment or subsequent processing.

2). Structural composition

1. Feeding device: responsible for evenly feeding the garbage materials to be sorted into the air drum separator, and the common ones are vibrating feeders, etc., which can ensure that the flow rate and speed of the materials entering the sorting machine are relatively stable, which is conducive to improving the sorting effect.

2. Sorting device: It is the core part of the air drum separator, including the fan that generates the airflow, the air duct for material dispersion and sorting, etc. The high-speed airflow generated by the fan forms a specific flow field in the air duct, so that the materials are separated according to the density and particle size differences. Some air drum separator are also equipped with special structures, such as spiral air ducts, cyclones, etc., which can further improve the sorting accuracy.

3. Discharge device: divided into light material discharge port and heavy material discharge port, which are used to discharge light materials and heavy materials after sorting respectively. In order to prevent material blockage and ensure smooth discharge, the design of the discharge port usually considers the fluidity and accumulation of materials.

4. Dust removal device: During the sorting process, a certain amount of dust will be generated. In order to reduce the pollution of dust emissions to the environment, air drum separator are usually equipped with dust removal devices, such as cyclone dust collectors, bag dust collectors, etc., which can effectively collect and process dust so that the discharged gas meets environmental protection standards.

3). Performance characteristics

1. Efficient sorting: It can effectively separate light and heavy materials in garbage, and the sorting efficiency is usually 95% The above greatly improves the subsequent treatment efficiency and resource recycling rate of garbage.

2. Wide range of applications: It can be applied to various types of garbage treatment, such as domestic garbage, industrial garbage, construction garbage, etc., and has good sorting effects for materials of different shapes, sizes and densities.

3. Low energy consumption and low noise: Compared with some traditional sorting equipment, the air drum separator has lower power and generates less noise during operation, which meets the requirements of environmental protection and energy saving.

4. Simple operation: The structure of the equipment is relatively simple, and the operation and maintenance are also relatively convenient. It does not require complex technology and professionals to operate, which reduces the operating cost.

5. Customizable: It can be customized according to the different needs of customers, such as processing capacity, sorting accuracy, equipment size, etc., which can better meet the personalized requirements of different users.

4). Application field

1. Domestic garbage treatment: In the sorting and treatment of domestic garbage In the production line, the air drum separator can be used as an important pre-treatment equipment to separate light materials such as plastics and paper from other heavy garbage in the garbage, providing convenience for subsequent recycling and treatment.

2. Industrial waste treatment: For the separation and recycling of various waste materials generated in the industrial production process, such as waste plastics, waste rubber, waste fiber and other light objects, the air drum separator also plays an important role, which helps to improve the resource recovery value of industrial waste.

3. Construction waste treatment: It can remove light materials such as wood, plastic, cloth in construction waste, improve the quality of recycled aggregates, enable them to be better used in the construction industry, and promote the resource utilization of construction waste.

4. Waste recycling industry: At waste recycling sites or recycling plants, air drum separator can be used for the preliminary sorting of various mixed wastes, separating wastes of different materials and densities, which is convenient for further classification, recycling and treatment.

5). Specification

| Air drum separator 800 | Air drum separator 1200 | Air drum separator 1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-07-16Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...