The working principle, advantages and application industry of horizontal baler

Working Principle

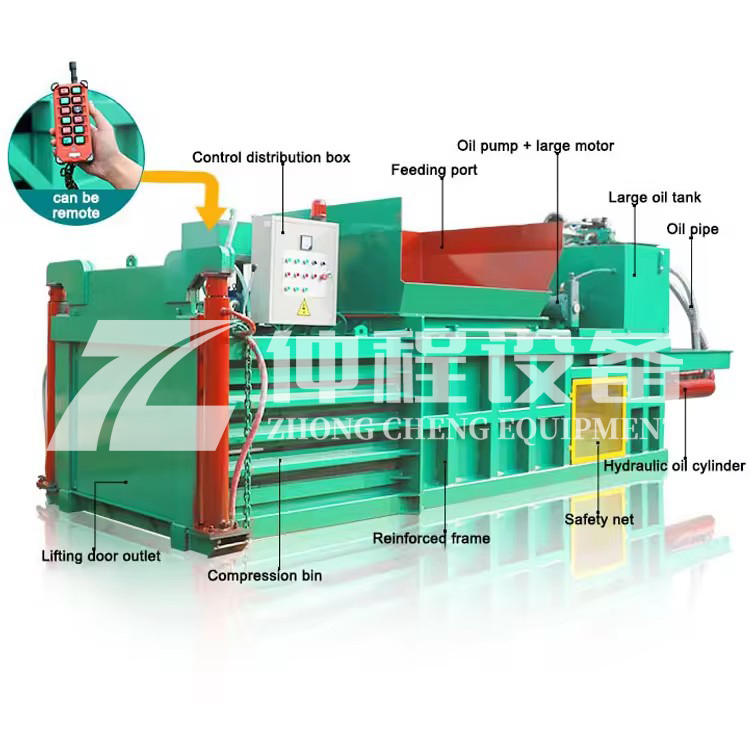

The working principle of a horizontal baler mainly includes the following steps:

- Feeding: Materials are fed into the baler through a conveyor belt or other means.

- Compression: Using the powerful pressure generated by a hydraulic or mechanical system, the materials inside the machine are tightly compressed.

- Shaping and Binding: Once the materials reach a certain density, they are shaped into a specific form and secured with steel wire or plastic straps.

Ejection: The compressed and bound material bales are then ejected from the other end of the machine.

Advantages

- Space Saving: It significantly reduces the volume of materials, making them easier to store and transport.

- Efficiency Improvement: With high levels of automation, it can quickly process large amounts of material.

- Environmental and Energy Efficiency: It aids in resource recycling and reuse, aligning with sustainable development principles.

- Ease of Operation: Most models are designed with user-friendly interfaces, making them easy to operate.

Wide Applicability: Suitable for various types of materials such as paper, plastic, and metal.

Application Industries

- Waste Recycling Industry: Including but not limited to the recycling of waste paper, plastics, and metals.

- Manufacturing Industry: Used for handling scrap materials produced during manufacturing processes.

- Agriculture: For example, the baling of crop residues like straw.

Logistics and Warehousing: Helps optimize warehouse space utilization and reduce transportation costs.

Primary Function

The primary function of a horizontal baler, in English, can be described as: "To compress loose materials into compact bales for easier handling, storage, and transportation, thereby improving space utilization and facilitating the recycling process."

This summary covers the basic working principle, main advantages, and the roles they play in different industries. I hope this helps!

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...