The Advantages and Main Structure of Garbage Air Separator

1).Advantages of garbage air separator

1. Efficient sorting capability

The garbage air sorting machine can quickly sort garbage of different specific gravity. For example, when processing municipal solid waste, it can separate lighter plastics, paper, etc. from heavier metals, glass, masonry, etc. in a short time. It has high working efficiency and can process several tons to dozens of tons of garbage per hour. For large-scale garbage treatment plants, it can effectively increase the speed of garbage treatment and meet the output requirements of garbage treatment.

And this sorting method is relatively accurate. It is sorted based on the density and aerodynamic properties of materials. By reasonably adjusting parameters such as air flow speed, different types of garbage can be accurately separated, which helps to improve the quality of subsequent garbage recycling. For example, when recycling plastic waste, a small amount of impurities mixed in it can be removed, improving the purity of the plastic and making it more suitable for the production of recycled plastic.

2. Significant environmental benefits

From the perspective of resource recovery, garbage air separators can effectively separate recyclable garbage components. It separates plastics, paper and other valuable materials from mixed waste, reducing the amount of these resources being landfilled or incinerated. Taking paper as an example, paper recycled through winnowing can be remade into new paper products, greatly saving wood resources.

At the same time, air classifiers help reduce the burden on landfills and incineration plants. After winnowing, non-recyclable waste components (such as some inorganic waste) can be landfilled more accurately, reducing the emissions of leachate and greenhouse gases (such as methane) produced by the decomposition of organic waste in the landfill. Moreover, since the amount of garbage that needs to be incinerated is reduced, the generation of harmful gases (such as dioxins, etc.) during the incineration process is also reduced accordingly.

3. Wide adaptability

Garbage winnowing machines can handle many types of garbage. Whether it is domestic waste from households or solid waste generated during industrial production, as long as the waste components differ in physical properties such as density, an air separator can be used for preliminary sorting. For example, in the processing of electronic waste, the air separator can initially separate the plastic part of the casing from the metal circuit board inside, which facilitates subsequent refined recycling.

It can also be integrated with other garbage disposal equipment. For example, it can be combined with garbage crushers, magnetic separators and other equipment to form a complete garbage disposal system. In this system, the air separator can sort the garbage after it is broken, or it can be air sorted first, and then the selected metal waste can be further purified through the magnetic separator to improve the efficiency and resource recovery rate of the entire garbage treatment process.

4. Running costs are relatively low

From the perspective of equipment energy consumption, although the garbage air separator requires power from fans and other equipment, its energy consumption is relatively low compared to some complex chemical treatment methods or high-precision mechanical sorting equipment. The power of the fan can be adjusted according to actual needs. When the processing capacity is small or the sorting requirements are not high, the fan speed can be appropriately reduced to reduce energy consumption.

Moreover, the maintenance cost of the air separator is also relatively reasonable. Its main component structure is relatively simple, without too many complicated mechanical structures and wearing parts. For example, its main moving part is the fan impeller. Under normal operating conditions, the impeller has a long service life and the replacement cost is relatively low. At the same time, other components such as feeding devices, sorting devices, etc. are also more convenient to maintain, and there is no need to frequently replace large components, thus reducing the long-term operating costs of the equipment.

The garbage air separator mainly consists of the following parts:

2).Main structure of garbage air separator

1. Feeding device

This is the entrance part where the garbage enters the winnowing machine. Its structural design should ensure that garbage can enter the interior of the air separator evenly and stably. For example, some feeding devices use conveyor belts or screw feeders. The conveyor belt can control the transmission speed to send the garbage into the air separator at an appropriate flow rate. The screw feeder can preliminarily classify the garbage to a certain extent. Squeeze and push to prevent garbage from blocking the feed port.

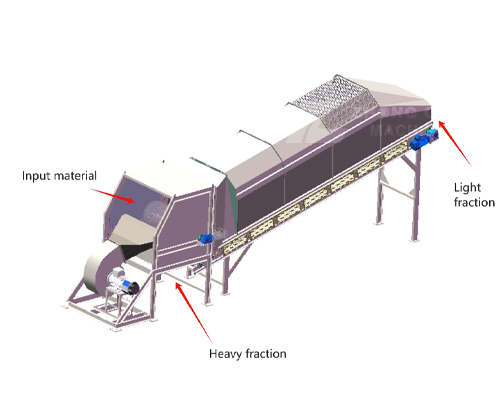

2. Winnowing room

This is the core part of the winnowing machine. There is an air flow channel inside the air separation chamber, and the air flow generated by the fan sorts the garbage in this space. Its shape and size are determined according to the processing capacity and sorting requirements of the air separator. Usually, the wall surface of the air separation chamber is relatively smooth to reduce the resistance of garbage and air flow, and has good sealing performance to prevent air flow leakage from affecting the sorting effect.

In the winnowing chamber, the speed and direction of airflow are key factors. Generally speaking, according to the size and weight of garbage particles, the air flow speed is controlled by adjusting the power of the fan so that lighter garbage (such as plastics, paper, etc.) can be taken away by the airflow, while heavier garbage (such as metal, glass, etc.) debris, etc.) fall due to gravity.

3. Fan system

A fan is a powered device that generates airflow. It includes components such as motors and fan impellers. The motor provides power for the rotation of the fan impeller. The high-speed rotation of the impeller causes air to be sucked in and accelerated to be discharged, forming a stable air flow. The power of the fan is selected according to the processing scale and sorting accuracy requirements of the air separator. For example, a garbage air separator with a large processing capacity needs to be equipped with a larger power fan to generate strong enough airflow to sort the garbage.

The fan system also includes a ventilation duct, which connects the fan and the winnowing chamber and guides the air flow into the winnowing chamber. The material of ventilation ducts generally requires a certain degree of strength and sealing to withstand air flow pressure and prevent air leakage.

4. Sorting device

It is mainly used to collect different types of garbage separated by air flow. At the exit of the air separation chamber, multiple channels or collection devices are usually provided. For example, lighter garbage (such as plastic films, etc.) is carried by the air flow to a specific collection channel and further collected through equipment such as cyclones or bag dust collectors. These equipment use the principle of centrifugal force or filtration to separate light garbage from the air flow. out; the heavier garbage falls directly into another collection container below the winnowing chamber. This collection container can be a funnel-shaped structure to facilitate centralized collection and subsequent processing of garbage.

5. Discharging device

Including light material discharging device and heavy material discharging device. The light material discharging device transports the sorted light waste (such as paper, plastic, etc.) to the designated storage area or the next processing link. This may be a conveyor belt or screw conveyor that moves light waste smoothly out of the winnower. The same applies to the heavy material discharging device, which is used to transport heavy garbage (such as metal blocks, stones, etc.) out of the air separator for subsequent recycling or processing.

6.Control system

The control system is used to adjust various working parameters of the air separator, such as fan speed, feed speed, etc. It can be a simple electrical control cabinet that adjusts the air volume and pressure of the fan by controlling the speed of the motor. Some advanced air separator control systems are also equipped with sensors that can monitor airflow speed, garbage flow and other parameters in the air separation chamber in real time, and automatically adjust the working status according to the preset sorting standards to achieve the best sorting effect.

3). Parameter

| Air Separator 800 | Air Separator 1200 | Air Separator 1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

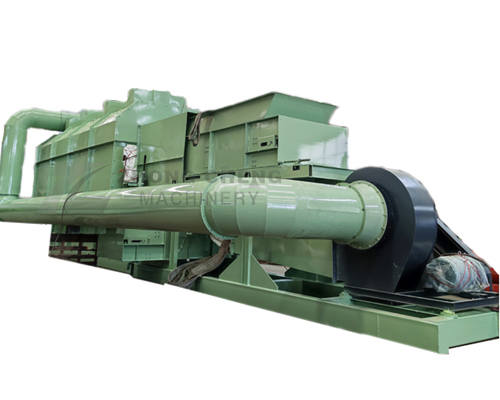

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-05-28Garbage screening drum screenTrommel screen is consisting of five parts: drum, frame, hopper, reducer and motor.After the material goes into the drum, it is screened along with the rotation...

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2023-01-12Waste Baler For MSWHigh density solid waste balers are the final step before sending waste to landfill. Horizontal balers designed and manufactured for this difficult job and prov...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...