Bounce screen technology details

Bouncing Screen (弹跳筛) Structure, Working Principle, Applications, and Benefits

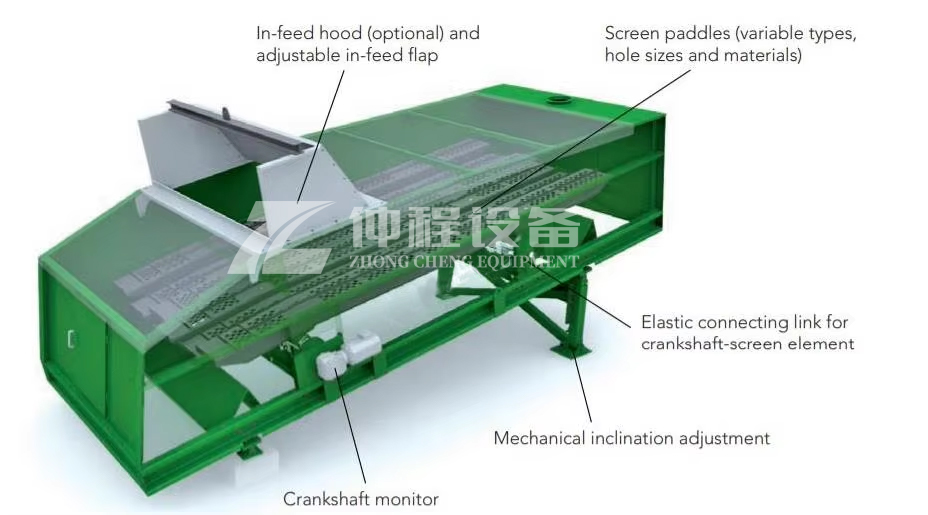

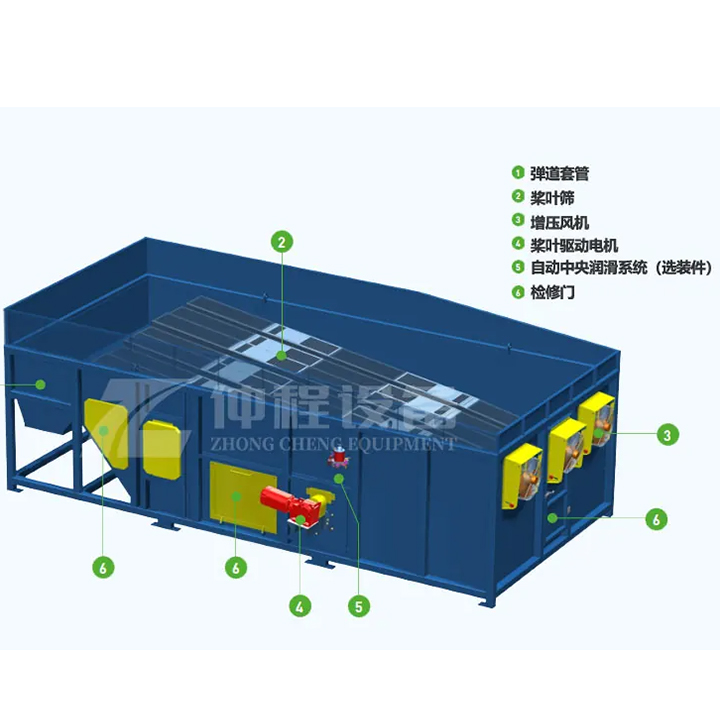

Structure

A bouncing screen, also referred to as a jumping screen or jigger, is designed with a unique structure that facilitates the separation of materials through a vertical oscillation mechanism. Its key components typically include:

- Screen Surface: Made from perforated plates or wire mesh, where material is placed for screening.

- Elastic Support System: Springs or other elastic elements that allow the screen to bounce.

- Exciter Mechanism: A motor-driven eccentric weight or similar device that creates the oscillating motion.

- Frame: Provides structural support and houses the exciter and elastic support system.

Material Inlet and Outlet: Ports for introducing material to be screened and removing the sorted material.

Working Principle

The working principle of a bouncing screen relies on its ability to impart a rapid up-and-down movement to the screen surface. The exciter mechanism causes the entire screen assembly to oscillate vertically at a high frequency. This motion lifts the material off the screen surface momentarily before dropping it back down. During this process, smaller particles fall through the screen openings while larger particles are ejected from the top. The constant bouncing action ensures thorough mixing and efficient separation of materials by size.

Applications

Bouncing screens are widely used in various industries for applications such as:

- Recycling Industry: Separating different types of recyclable materials like plastics, paper, and metals.

- Construction and Demolition Waste Management: Sorting construction debris to facilitate recycling.

- Agriculture: Cleaning and grading agricultural products such as seeds, grains, and fruits.

- Mining and Mineral Processing: Separating valuable minerals from waste rock.

- Food Processing: Sorting food items according to size, shape, and density.

Benefits

The advantages of using a bouncing screen include:

- High Efficiency: Rapid and continuous screening process allows for high throughput rates.

- Effective Separation: Ensures precise separation of materials into different sizes.

- Low Power Consumption: Operates efficiently with minimal energy requirements.

- Reduced Blockage: The bouncing action helps prevent clogging of screen holes.

- Compact Design: Takes up less space compared to some other types of screening equipment.

- User-Friendly Operation: Simple operation and maintenance procedures make it accessible for operators.

Versatility: Suitable for a wide range of materials and can handle wet or sticky substances effectively.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2024-07-12Crush to Create: The Ultimate Eco-Friendly Plastic Shredder RevolutionThe working principle of a plastic shredder is mainly to tear large plastic materials into small pieces or fragments through mechanical force, in order to facil...

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...