Horizontal Baling Machine: An Essential Tool for Material Compression and Waste Management

Introduction:

A Horizontal Baling Machine is a type of industrial equipment designed to compress various materials into compact bales for easier handling, storage, and transportation. This machinery is widely used in recycling centers, waste management facilities, and manufacturing plants to process recyclable materials like paper, cardboard, plastics, and textiles, as well as agricultural products.

Working Principle:

The working principle of a horizontal baler revolves around the concept of compression. Materials are fed into the machine's hopper where they are pushed by a hydraulic ram into a chamber. The hydraulic system applies significant pressure to compact the materials into dense bales. Once the desired density is achieved, the bale is tied with wire or straps using an integrated tying mechanism. After securing the bale, it can be ejected from the machine for further processing or shipment.

Structure:

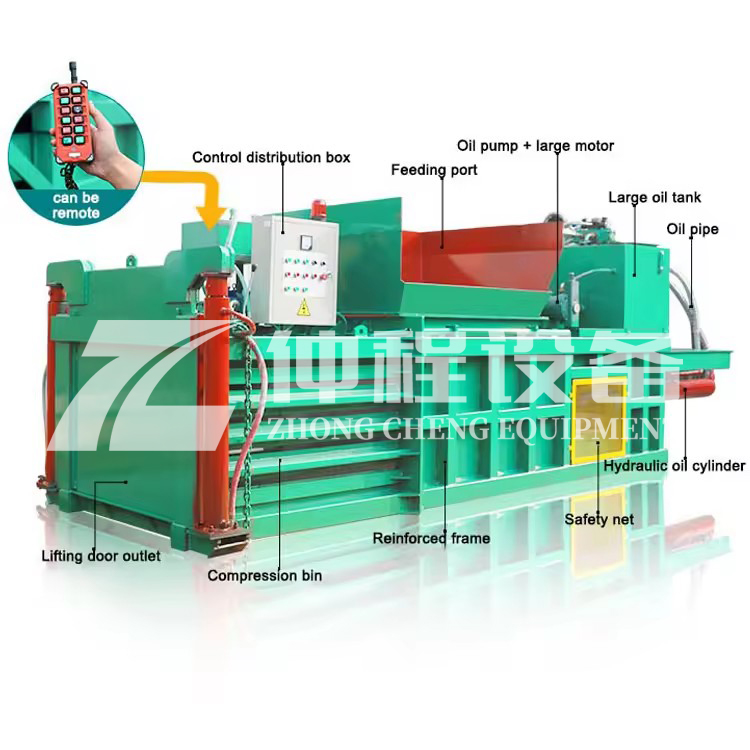

- Feeding System: Consists of a hopper that receives the material to be baled.

- Compression Chamber: Where the material is compressed by a hydraulic ram.

- Hydraulic System: Provides the force necessary for compression.

- Tying Mechanism: Automatically ties the compressed material with wire or straps.

- Ejection System: Removes the finished bale from the compression chamber.

Control Panel: Allows operators to manage the machine's operation.

Application Industries:

- Recycling Industry: For processing waste paper, cardboard, plastics, and metals.

- Agriculture: To bale hay, straw, and other crop residues.

- Waste Management: For compressing municipal solid waste.

- Manufacturing: To handle production waste like scrap metal, plastic offcuts, and packaging materials.

Logistics and Warehousing: For optimizing space and reducing shipping costs by compacting goods.

Horizontal baler features:

Hydraulic system, with overflow and prevent system overload function, stable operation;

Simple installation, installation without foot screws, in the place without power, diesel engine can be used as power;

The spherical structure is used between the push cylinder and the push head, which has good reliability and long service life of the oil seal;

Feed mouth with distributed shear knife, high cutting efficiency;

Low noise hydraulic circuit design, excellent efficiency, low fault;

Horizontal structure, can be equipped with conveyor belt feeding or manual feeding;

Button operation, PLC control, safe and reliable;

Can be customized, compression chamber size and package size can be customized according to customer requirements;

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...