How to choose an appropriate ballistic separator

A ballistic separator is a type of mechanical sorting equipment commonly used in waste management

and recycling systems, particularly for municipal solid waste (MSW). The primary function of a ballistic

separator is to differentiate materials based on their shape and size, utilizing a unique motion that helps

separate lighter and heavier items.

Basic Principle:

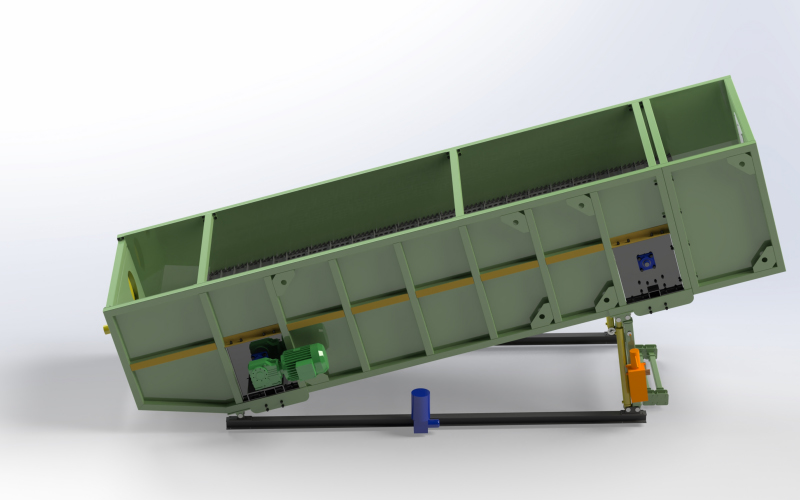

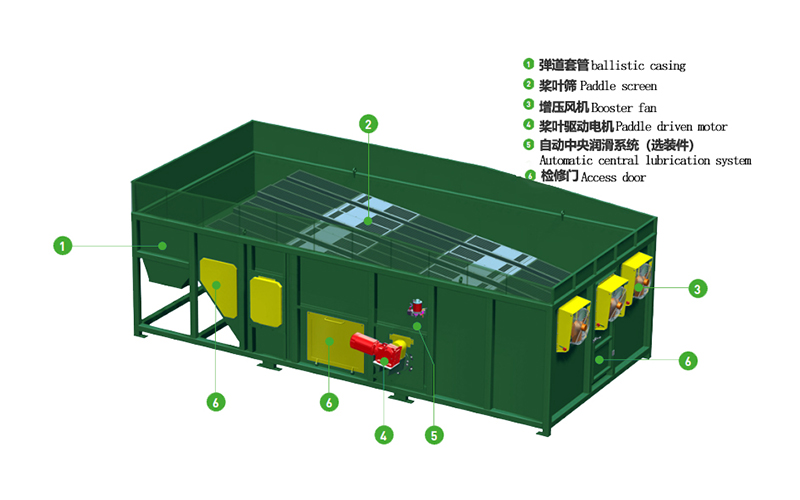

The concept behind a ballistic separator is based on a ballistic motion—a motion where the waste

material is subjected to a combination of high-frequency shaking and vertical or horizontal movement.

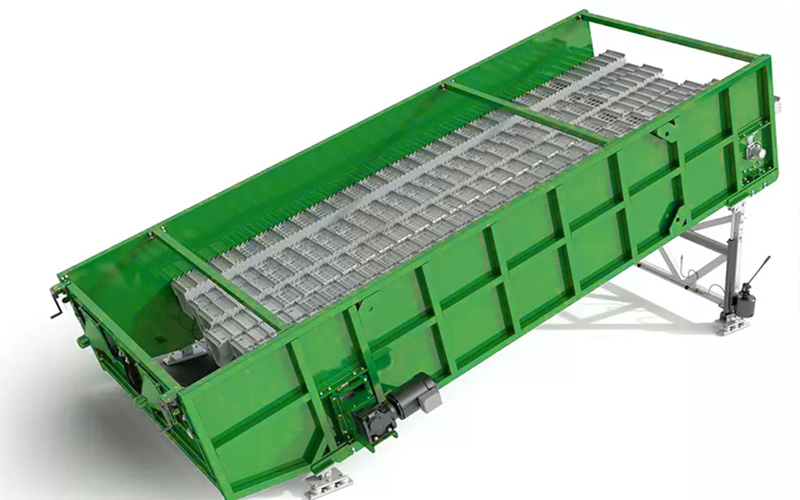

The separator typically consists of a set of inclined or horizontal screens through which the waste flows.

These screens are mounted on a mechanism that allows them to vibrate or "shake" in a specific pattern.

How It Works:

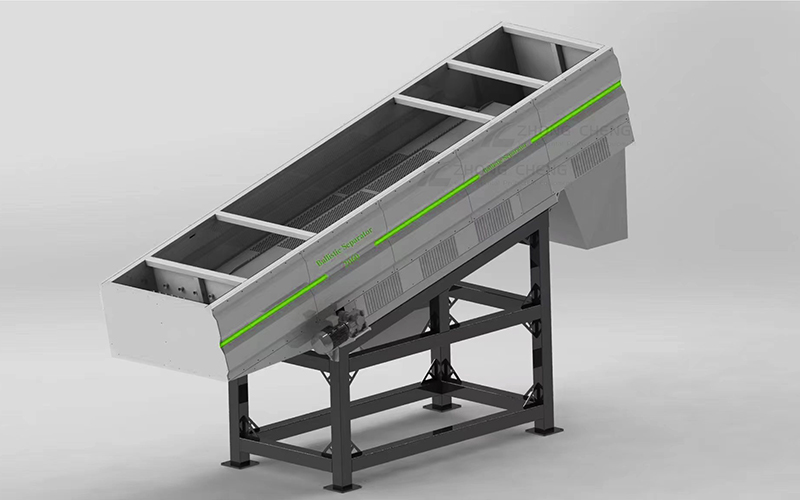

Vibration/Movement: The separator’s screens move in a rapid, vibrating manner, causing the materials

placed on them to be thrown into the air slightly. This action mimics a ballistic trajectory, where lighter

materials tend to "fly" further away than heavier ones. The motion is often referred to as “ballistic” because

the materials behave like projectiles.

Separation Based on Shape: The separator uses the different physical properties of the materials to create

separation:

Lighter materials (such as paper, plastics, and textiles) tend to move in the same direction of the shaker

motion and often land further down the conveyor.

Heavier materials (such as metals, glass, and larger debris) stay closer to the vibrating screen or may even

bounce, depending on their weight and shape.

Screen Configuration: The screens or grids are usually designed with openings of various sizes. Small objects

may fall through the screens, while larger objects remain on top and are moved to a different area. The

configuration of the screens determines the size and type of materials that are separated.

Air Flow or Additional Sorting: Some ballistic separators are combined with other technologies (like air classifiers)

to further enhance separation efficiency. For instance, lighter items can be blown off the surface by air jets,

while heavier ones continue through the sorting process.

Key Features of a Ballistic Separator:

Shape and Size Sensitivity: Ballistic separators are particularly effective at separating materials based on their

shape and size rather than their weight alone. For example, flat, flexible items like cardboard or plastic films

are separated from denser, rigid items like metals and glass.

High Throughput: They can handle large volumes of mixed waste efficiently, making them suitable for large-scale

recycling facilities and waste sorting plants.

Minimal Material Degradation: The motion involved in a ballistic separator is gentle enough that materials aren't

crushed or degraded in the process. This helps maintain the integrity of the recyclable materials, which is crucial

for high-quality recovery.

Applications:

Ballistic separators are used in a variety of waste sorting scenarios, including:

Municipal Solid Waste (MSW): Separating recyclable materials (paper, plastics, etc.) from non-recyclable

materials (glass, metals, etc.).

Construction and Demolition Waste: Sorting out large items like wood and metal from smaller debris.

Plastic and Paper Sorting: Separating different types of plastics or paper materials based on size and shape.

Advantages of Ballistic Separators:

High Efficiency: They can separate materials quickly, making them ideal for fast-paced sorting environments.

Selective Sorting: They provide a high level of accuracy in sorting materials by size and shape, which is

crucial for recycling operations.

Adaptable to Various Waste Streams: Ballistic separators can handle a wide range of waste types, from

MSW to industrial or construction debris.

Reduced Maintenance: Compared to other mechanical sorters (like air classifiers or trommel screens),

ballistic separators often require less maintenance.

When choosing a suitable ballistic separator for a municipal solid waste (MSW) sorting system,

there are several factors to consider to ensure that it performs efficiently and meets the specific needs

of your waste sorting process.

Here’s a step-by-step guide to help you make an informed decision:

1. Understand the Characteristics of Your Waste

Waste Composition: The types of materials in your MSW (e.g., paper, plastic, metal, organic waste)

will determine how well different separators will perform.

Size Distribution: A ballistic separator is more effective when there’s a varied size distribution. If your

waste stream has many large items, you may need a separator that can handle them efficiently.

Moisture Content: Wet or sticky waste materials can clog or affect the performance of the separator,

so the moisture content of your MSW should be considered.

2. Separator Design and Performance

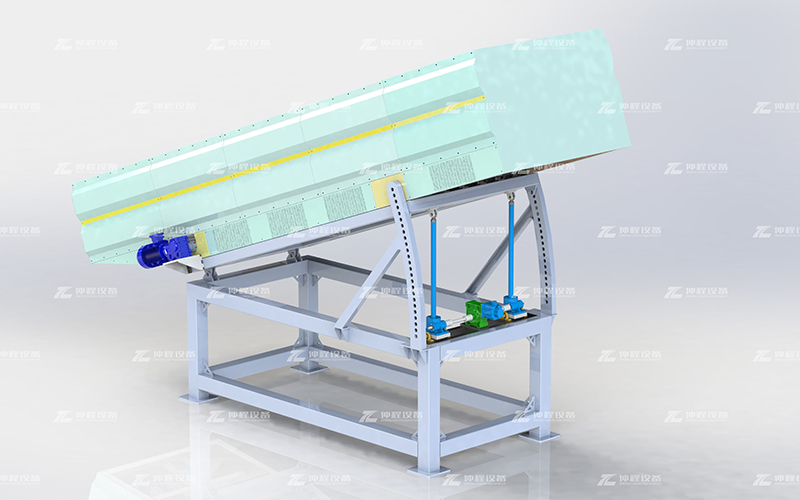

Ballistic Motion: Ballistic separators use a high-frequency motion to "shake" the waste, causing lighter

materials (like paper and plastic) to move in different directions than heavier ones (like metals and glass).

The separator should be capable of achieving a balance between separating light and heavy materials

without losing efficiency.

Screening Angle and Stroke: The angle at which the separator operates and the stroke length can influence

how materials are sorted. For example, a steeper angle may be necessary for larger or heavier waste items.

Capacity: Match the separator’s processing capacity to the throughput of your waste stream. This is typically

measured in tons per hour (TPH).

3. Adjustability and Customization

Adjustable Settings: Some ballistic separators offer adjustable settings for stroke length, speed, and the angle

of inclination. These features can allow you to fine-tune the machine to suit your specific waste stream, which

can be especially useful if the waste composition changes over time.

Modular Design: If your waste composition changes or increases, a modular design could allow for easy

upgrades or adjustments to the system.

4. Separation Efficiency and Recovery

Separation Accuracy: Make sure that the ballistic separator is effective at differentiating materials that need to be

sorted out. For example, if you need to separate paper from plastic or cardboard from glass, the separator

must be able to do so without mixing too much.

Material Recovery: Consider the separator’s ability to recover valuable materials like recyclables (e.g., paper, plastics,

metals). More efficient recovery systems can improve the economic viability of your operation.

5. Maintenance and Durability

Ease of Maintenance: Choose a separator that is easy to clean and maintain, as MSW can contain contaminants

that may clog or damage the machine. Regular maintenance and long service intervals will reduce downtime.

Durability: Since ballistic separators are subject to high wear and tear due to the motion and materials being processed,

the build quality and material choice are crucial for longevity.

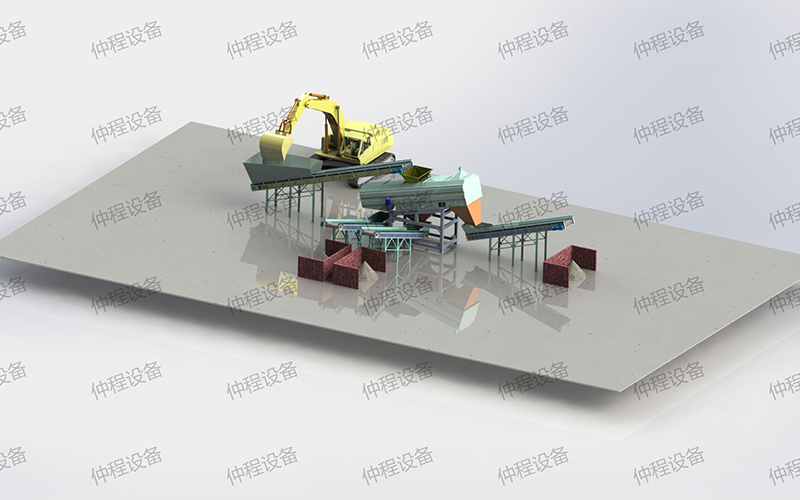

6. Space and Integration

Footprint: Consider the physical space available for the separator within your sorting facility. Ensure that it fits within

the layout of your sorting system.

Integration: Ensure that the separator integrates well with other equipment in your sorting line, such as conveyors,

shredders, and air classifiers. The entire system should work together seamlessly for optimal performance.

7. Energy Consumption and Operating Costs

Energy Efficiency: Look for a separator that is energy-efficient, especially if you are dealing with high-throughput waste

sorting operations. Lower energy consumption can help reduce overall operational costs.

Operating Costs: Take into account not only the initial cost of the separator but also its operating costs, including power,

maintenance, and any spare parts that may be required.

8. Supplier and Support

Reputation of the Supplier: Choose a reputable manufacturer or supplier with a proven track record in MSW sorting equipment.

Support and Spare Parts: Ensure the supplier provides good customer support and has readily available spare parts

for the equipment.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...