Magnetic Separators: Essential Equipment in Waste Sorting

In the realm of waste management and recycling, efficient sorting is crucial for processing different types of waste. Among the various machines used for this purpose, magnetic separators, also known as iron removers or de-ironing equipment, play a vital role in separating ferrous metals from mixed waste streams.

Magnetic separators utilize powerful magnets to attract and remove iron and steel contaminants from materials such as plastics, wood, glass, and non-ferrous metals. This process not only purifies the material flow but also recovers valuable ferrous metals that can be recycled. The ability to extract these materials effectively helps reduce landfill use, supports environmental conservation, and contributes to resource efficiency.

Types of Magnetic Separators:

1. Overband Magnets:

Suspended over conveyor belts, overband magnets are designed to capture large pieces of ferrous metal as they move along with the waste stream. These magnets are particularly useful in removing bulky iron objects like screws, nuts, bolts, and other machinery parts.

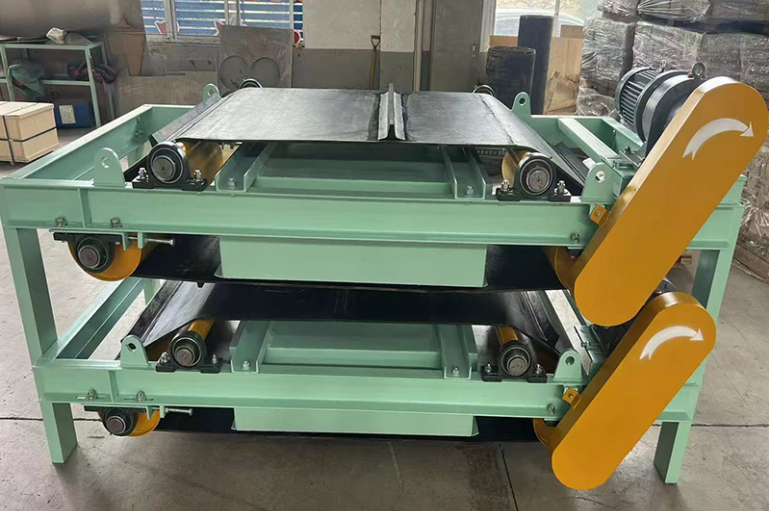

2. Drum Magnets:

Consisting of a rotating drum with an internal magnet system, drum magnets continuously separate smaller ferrous particles from finer material fractions. As the drum rotates, it carries the attracted metal away from the waste flow and releases it into a collection bin.

3. Plate Magnets:

Installed within chutes or above conveyors, plate magnets intercept smaller ferrous debris as materials slide over them. They are effective for inline processes where space is limited.

4. Pulley Magnets:

Integrated into the head pulley of a conveyor system, pulley magnets provide a compact solution for continuous separation of fine iron particles. The magnetic field extends beyond the belt edge, ensuring thorough removal of ferrous contaminants.

Benefits of Using Magnetic Separators:

- Enhanced purity of recycled materials, leading to higher quality end products.

- Protection of downstream equipment from damage caused by metallic fragments.

- Increased efficiency of the recycling process, reducing manual sorting efforts.

- Contribution to sustainability by facilitating the recovery of recyclable metals.

Maintenance and Safety Considerations:

To ensure optimal performance, regular maintenance of magnetic separators is necessary. This includes cleaning collected metal from the magnets, inspecting for wear and tear, and verifying the strength of the magnetic field. Safety measures must also be observed, especially when handling strong magnets, which can pose risks if not managed properly.

As the importance of sustainable practices continues to grow, so does the reliance on advanced technologies like magnetic separators. By integrating these devices into waste sorting facilities, we can improve the effectiveness of our recycling efforts, conserve resources, and protect the environment for future generations.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...