Material Handling, Magnetic Separation, and Metal Detection Equipment for the Recycling Industry

Material Handling, Magnetic Separation, and Metal Detection Equipment for the Recycling Industry

Magnetic Separation for Recycling

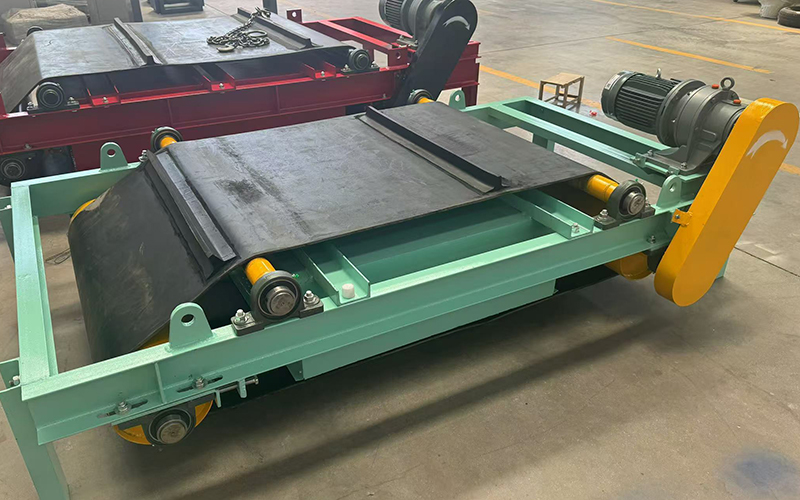

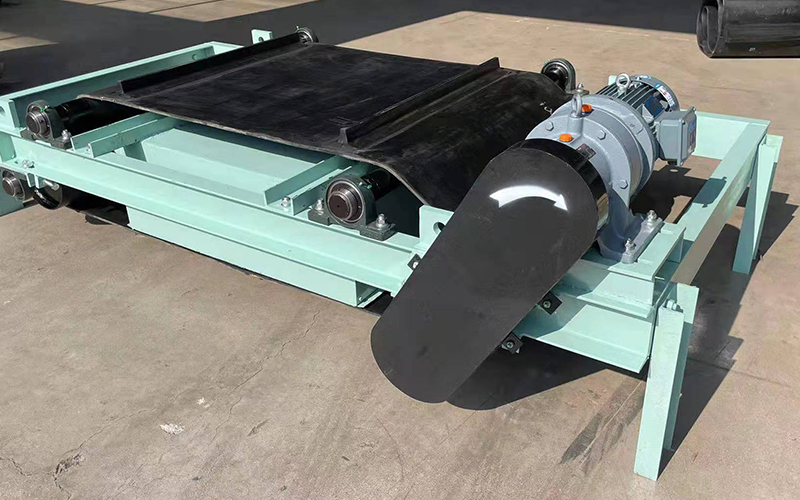

Magnetic separation utilizes powerful magnets to pull out ferrous metal contaminants from a processing

line, trapping them against the face of the magnet and ensuring they cannot re-enter the material stream.

The strength of the magnetic field means that continued material flow, no matter how rapid, will not be

able to dislodge the ferrous material from where it has been initially trapped.

magnetic separation equipment suitable for gravity free-fall systems, in-line systems, and liquid

processing systems.

Metal detection for Recycling

Metal detection systems generate an electromagnetic field that material flows through, sensing and

rejecting any ferrous or non-ferrous metal that is hidden within the material.

In situations where a magnetic separator may be unable to remove a non-ferrous contaminant, such as

aluminum, a metal detector is able to sense this metal and remove the contaminated section of material

from the greater flow of operations.

metal detection equipment suitable for gravity free-fall, pneumatic, and all conveyor applications, with three

different packages available for electronics customization.

From feeding material into shredders with magnetic and metal detection separation capabilities, transferring

that shredded material to a granulator or to a high intensity magnetic separator over a vibratory feed feeding

an Eddy Current or Drum Separator, we has the complete line.

All of our products are custom designed by our engineers according to the customer’s specifications, allowing

for them to integrate seamlessly into the existing production environment. Our team of engineers work with

each customer to deliver a personalized piece of equipment with the physical dimensions to best fit your space

and flow stream, and with the magnetic components that best suit your separation, detection, and conveying needs.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-08-07Tire double shaft shredderOperation:Feeding: Whole or pre-cut tires are fed into the shredder through an inlet hopper.Shredding: As the tires enter the shredding chamber, the rotating cu...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...