metal double shaft shredder

Date:2024-11-05

View: Point

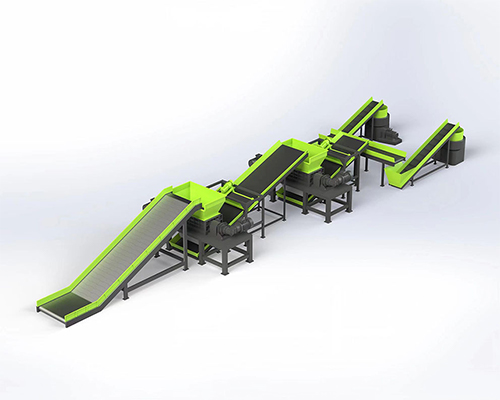

A metal double shaft shredder is a specialized piece of equipment designed for the processing and recycling of various types of scrap metal materials. It's widely used in the metal recycling industry to reduce the size of large, bulky, and often hard metal waste into smaller, more manageable pieces. This makes it easier for the material to be further processed or transported. Here’s an overview of its key features and benefits:

Structure and Working Principle

- Dual Shaft Design: The core of a metal double shaft shredder consists of two counter-rotating shafts, each equipped with multiple cutting knives. As the material enters the shredder, the knives on the two shafts work together to shear, crush, and tear the material into smaller pieces.

- Heavy-Duty Knives: The knives are typically made from high-strength alloy steel to handle different types of metal materials, ensuring durability and longevity.

- Power System: The shredder is driven by a high-torque reducer motor, providing sufficient power to process tough and hard metal materials.

Advantages

- High Efficiency: Capable of processing large volumes of scrap metal quickly, increasing productivity.

- Versatility: Suitable for a wide range of metal materials, including old car shells, scrap appliances, steel scrap, aluminum scrap, and more.

- Volume Reduction: Significantly reduces the volume of metal waste, making it easier to store and transport.

- Environmental Benefits: Promotes resource recycling and helps protect the environment.

- High Safety: Equipped with overload protection systems that automatically stop or reverse the machine when the load exceeds the set value, protecting the equipment from damage.

- Easy Maintenance: Modular design facilitates routine maintenance and part replacement.

Applications

- Metal Recycling: Widely used in the metal recycling industry to convert scrap metal into reusable forms.

- Steel Smelting: Processed metal waste can be directly fed into steel furnaces, improving smelting efficiency and steel quality.

- Resource Recovery: In the resource recovery and reuse sector, metal double shaft shredders can also handle other types of waste, such as scrap wires, cables, and obsolete electronics, maximizing resource utilization.

Common Specifications

- Capacity: Varies depending on the model, ranging from a few hundred kilograms to several tons per hour.

- Power: Typically ranges from 30 kW to over 200 kW, depending on the size and application.

- Dimensions: Can vary significantly, but common sizes include machines that are several meters long and wide.

- Materials Handled: Steel, aluminum, copper, brass, and other ferrous and non-ferrous metals.

Maintenance Tips

- Regular Inspection: Regularly check the condition of the knives and replace them as needed to maintain optimal performance.

- Lubrication: Ensure that all moving parts are properly lubricated to reduce wear and tear.

- Cleaning: Clean the shredder regularly to prevent buildup of debris and ensure smooth operation.

- Training: Train operators to use the equipment correctly and safely to avoid accidents and prolong the life of the machine.

Overall, a metal double shaft shredder is an essential tool in the metal recycling and waste management industries, offering efficient, reliable, and environmentally friendly solutions for handling scrap metal.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

Zhongcheng Machinery Will Be There Whenever Wherever Whatever You Need

You Are Welcome to : phone call, Message, Wechat, Email& Seaching us, etc.

Email:

sales@zchmachinery.com

Whatsapp/Phone:

+8618738194110

hot Products

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

relate news

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...