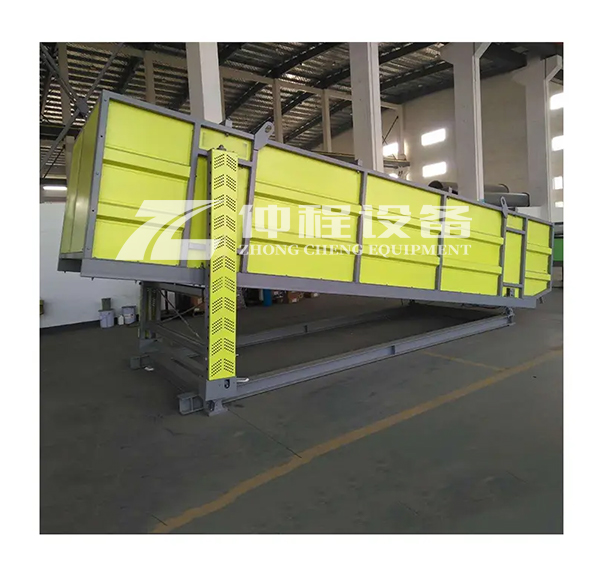

New tool for efficient separation: Bounce screen shines in many industries

Introduction to Bouncing Screen

Definition

A Bouncing Screen, also known as a Jumping Screen or Bouncing Sieve, is a type of screening equipment used to separate materials into different sizes based on their particle dimensions. It is widely used in various industries for its efficiency and simplicity.

Working Principle

The Bouncing Screen operates by using a motor-driven eccentric weight to create a vertical vibration. This vibration causes the material on the screen to bounce up and down, facilitating the separation of particles. The screen is typically inclined at a specific angle to help the material move from one end to the other. As the material bounces, smaller particles pass through the screen openings, while larger particles remain on top and move towards the discharge end.

Components

- Screen Deck: The surface where the material is placed and separated.

- Eccentric Weight: A component attached to the motor that generates the vertical vibration.

- Motor: Provides the necessary power to drive the eccentric weight.

- Support Frame: Holds the screen deck and other components in place.

- Inclination Adjustment: Mechanism to adjust the angle of the screen for optimal performance.

Vibration Dampeners: Reduce the transmission of vibrations to the surrounding structure.

Applications

- Mining and Quarrying: Sorting and grading of crushed stone, gravel, sand, and other aggregates.

- Recycling: Separating waste materials such as plastics, paper, and metals for recycling processes.

- Agriculture: Cleaning and grading seeds, grains, and other agricultural products.

- Construction: Screening and classifying construction materials like concrete and asphalt.

- Chemical Industry: Sieving powders and granules to ensure uniform particle size before packaging or further processing.

Advantages

- High Efficiency: The bouncing action ensures thorough and even distribution of material, leading to high throughput and precise separation.

- Low Maintenance: The simple design with fewer moving parts reduces the need for frequent maintenance and repairs.

- Adjustable: The angle and amplitude of the screen can be easily adjusted to suit different materials and screening requirements.

- Cost-Effective: Compared to more complex screening equipment, a bouncing screen is often less expensive to purchase and operate.

- Compact Design: These screens take up less space, making them ideal for operations with limited area.

Environmental Friendly: They typically consume less energy, contributing to lower operational costs and a reduced carbon footprint.

Disadvantages

- Limited Capacity: May not be suitable for very high-volume applications.

- Material Constraints: Some sticky or cohesive materials may not separate well using this method.

- Noise: The operation can generate significant noise, which may require additional sound dampening measures.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Spring Cone CrusherSpring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crush...

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2024-04-25Recycling Finger ScreensFinger screen is a type of screening equipment used to separate materials based on size. Unlike traditional screens, finger screens consist of a series of paral...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...