Talk about the vibration screen

Features of Shaking Screens in Waste Sorting Equipment

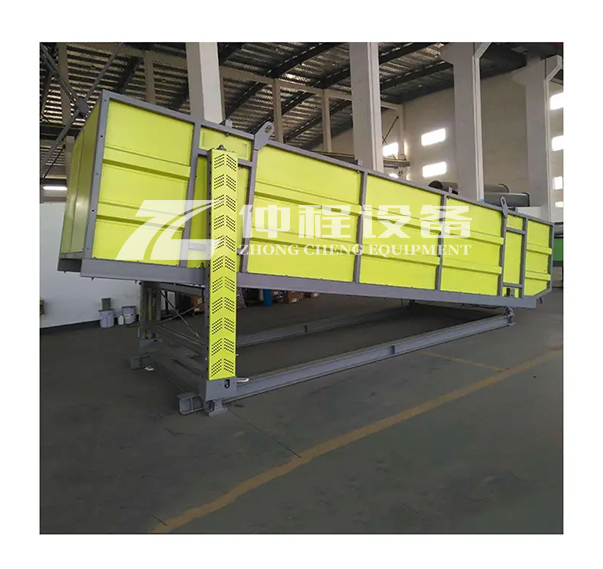

Vibrating screens, also known as shaking screens, are a critical component in waste sorting and processing systems. These screens are designed to efficiently separate materials based on size, density, and shape, making them indispensable in various applications within the waste management industry. Here are some key features and advantages of vibrating screens:

1. High Efficiency

- Throughput Capacity: Vibrating screens are capable of handling large volumes of material, ensuring high throughput rates. This makes them suitable for high-capacity operations in municipal solid waste (MSW) facilities, construction and demolition (C&D) waste processing, and industrial waste management.

- Separation Accuracy: The consistent and rapid vibration of the screen ensures precise and accurate separation of materials. This is particularly important for sorting out contaminants and recovering valuable resources.

2. Versatility

- Material Compatibility: Vibrating screens can handle a wide range of materials, including organic waste, plastics, metals, and aggregates. They are adaptable to different types of waste and can be customized to meet specific sorting needs.

- Screening Media: The screens can be equipped with various types of media, such as wire mesh, perforated plates, and polyurethane panels, to accommodate different particle sizes and material characteristics.

3. Durability and Reliability

- Robust Construction: Vibrating screens are built to withstand the harsh conditions often found in waste processing environments. They are typically constructed from high-strength steel and other durable materials.

- Low Maintenance: The simple and robust design of vibrating screens results in low maintenance requirements. Regular inspection and replacement of worn parts can keep the equipment running smoothly for extended periods.

4. Energy Efficiency

- Optimized Vibration: Advanced designs incorporate optimized vibration patterns that maximize screening efficiency while minimizing energy consumption. This is achieved through the use of balanced vibrators and adjustable settings.

Control Systems: Modern vibrating screens often come with sophisticated control systems that monitor and adjust the vibration frequency and amplitude in real-time, ensuring optimal performance and energy efficiency

5. Customizability

- Modular Design: Many vibrating screens are modular, allowing for easy customization and expansion. Additional decks and screens can be added to handle multiple size fractions simultaneously.

- Adjustable Settings: The angle of inclination, vibration frequency, and amplitude can be adjusted to suit different materials and processing requirements. This flexibility ensures that the screen can be fine-tuned for maximum efficiency.

6. Environmental Benefits

- Reduced Landfill Usage: By effectively separating and recovering valuable materials, vibrating screens help reduce the amount of waste sent to landfills. This contributes to environmental sustainability and resource conservation.

- Improved Quality of Recycled Materials: Precise separation ensures that the recovered materials are of high quality, making them more suitable for reuse and recycling processes.

7. Operational Safety

- Enclosures and Guards: Many vibrating screens are equipped with enclosures and guards to protect operators from moving parts and potential hazards. This ensures a safe working environment.

Noise Reduction: Advanced designs incorporate noise reduction features, such as sound-dampening materials and enclosures, to minimize noise pollution in the workplace.

8. Integration with Other Equipment

- Feeders and Conveyors: Vibrating screens can be easily integrated with feeders and conveyors to create a seamless and efficient waste processing system. This integration ensures a continuous flow of material and enhances overall productivity.

Automated Control Systems: Modern vibrating screens can be integrated with automated control systems that monitor and control the entire waste sorting process, from feeding to discharge.

BS04 BS06 BS08 BS10 BS12 Paddy Number 4 4 - 6 6 - 8 6 - 8 6 - 10 Paddle length 5.5m 5.5m 5.5m 5.5m 5.5m Angle adjustment 0 – 25° 0 – 25° 0 – 25° 0 – 25° 0 – 25° Sieve hole size 20-80 mm 30-80 mm 30-80 mm 30-80 mm 30-80 mm Fan Number 2 - 4 2 - 4 2- 4 2 - 4 2 - 4 Power 5.5kw 7.5kw 11kw - 15kw 11kw -18.5kw 22kw Throughput 0-30 m³/h 30-50 m³/h 50-70 m³/h 70-90 m³/h 90-120 m³/h

Vibrating screens are a crucial element in waste sorting and processing systems, offering high efficiency, versatility, durability, and environmental benefits. Their ability to handle a wide range of materials and their customizable nature make them an essential tool in the waste management industry. As technology continues to advance, we can expect even more innovative features and improvements in the performance of vibrating screens.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2023-01-12Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2024-07-16Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...