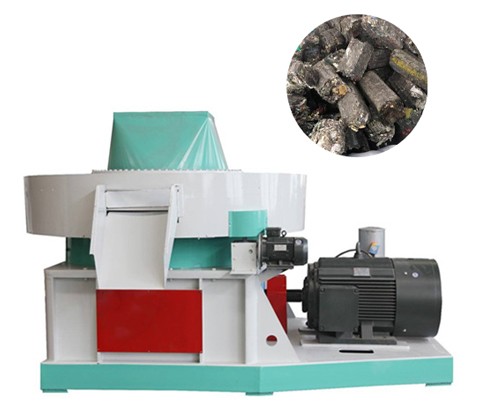

Waste Management Solution with RDF Briquette Press Machine

1). RDF (Refuse Derived Fuel) rod making machine,also called RDF Briquette Press Machine, is a mechanical equipment specially used to compress RDF into rod-shaped fuel. RDF is an alternative fuel made from urban solid waste (such as non-hazardous waste such as plastics, paper, textiles, etc.) after pretreatment. It can be used to replace traditional fossil fuels such as coal or natural gas in industrial facilities such as cement plants and power plants.

2). The main features of RDF Briquette Press Machine include:

1. Efficient compression: Through a powerful hydraulic system, the loose RDF material is compressed into a rod or block with higher density, improving transportation efficiency and storage capacity.

2. Environmental protection and energy saving: RDF, as an alternative fuel, helps to reduce dependence on fossil fuels, reduce greenhouse gas emissions, and realize the recycling of resources.

3. Strong adaptability: It can adapt to different types of raw materials, including but not limited to various pre-treated wastes, to meet the needs of different users.

4. High degree of automation: Modern RDF Briquette Press Machines are usually equipped with advanced control systems, which can realize fully automated operation from feeding to finished product discharging, reduce labor costs and improve production efficiency.

5. Safe and reliable: Safety factors are fully considered during the design, such as emergency stop button, overload protection and other functions to ensure the safety and stability of equipment operation.

6. Easy maintenance: The modular design is convenient for daily maintenance and troubleshooting, extending the service life of the equipment.

3). Application scenarios:

1. Energy industry: used as an alternative fuel in thermal power plants, biomass power plants, etc.

2. Manufacturing industry: can be used for heat energy supply in cement production process.

3. Chemical industry: as a heat source required for certain chemical reactions.

Other industrial uses: such as heating applications in papermaking, steel and other industries.

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...