Bouncing Screen: An Essential Tool for Material Separation

Bouncing Screen (also known as a Jumping Screen or Bouncing Sieve) is a type of screening equipment used in the processing industry to separate materials based on their size. This device is particularly useful in industries such as mining, construction, and recycling for sorting out different sizes of granular or powdered materials.

How It Works:

The core principle behind a bouncing screen involves the use of a vibrating mechanism that causes the screen to oscillate or bounce. This motion helps to spread the material evenly across the screen surface and allows smaller particles to pass through the openings while larger particles remain on top. The bouncing action can be achieved through various means, including:

- Mechanical Drives: Utilizing an eccentric shaft or crank mechanism to create the necessary vibration.

- Air Blowers: Using compressed air to cause the screen to vibrate.

Electromagnetic Vibrators: Employing electromagnetic forces to induce vibration in the screen.

Key Components:

- Screen Surface: Made from a variety of materials, such as metal wire mesh, polyurethane, or rubber, depending on the application and the material being processed.

- Vibration Mechanism: The system responsible for generating the oscillating or bouncing movement.

- Support Structure: A robust frame designed to support the weight of the screen and the material being processed.

- Drive Motor: Provides the power needed to operate the vibration mechanism.

- Material Feed System: Ensures a consistent supply of material onto the screen.

Discharge Chutes: Directs the separated materials into appropriate bins or conveyors for further processing or storage.

Applications:

- Mining: Separation of ore and minerals.

- Construction: Sorting of aggregates and recycled concrete.

- Agriculture: Grading of seeds, grains, and other agricultural products.

- Recycling: Processing of waste materials, including plastics and metals.

Pharmaceuticals: Sieving of powders and granules during production processes.

Advantages:

- Efficiency: High throughput and precise separation.

- Versatility: Capable of handling a wide range of materials and particle sizes.

- Low Maintenance: Generally simple design with fewer moving parts compared to some other types of screens.

Durability: Built to withstand heavy use and harsh conditions.

Maintenance:

Regular maintenance is crucial for the optimal performance of a bouncing screen. This includes checking the tension of the screen mesh, lubricating moving parts, inspecting for wear and tear, and ensuring that the drive motor is functioning correctly.

In summary, the bouncing screen is a vital piece of equipment in many industrial settings, offering a reliable method for separating materials by size, which is essential for optimizing downstream processes and product quality.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

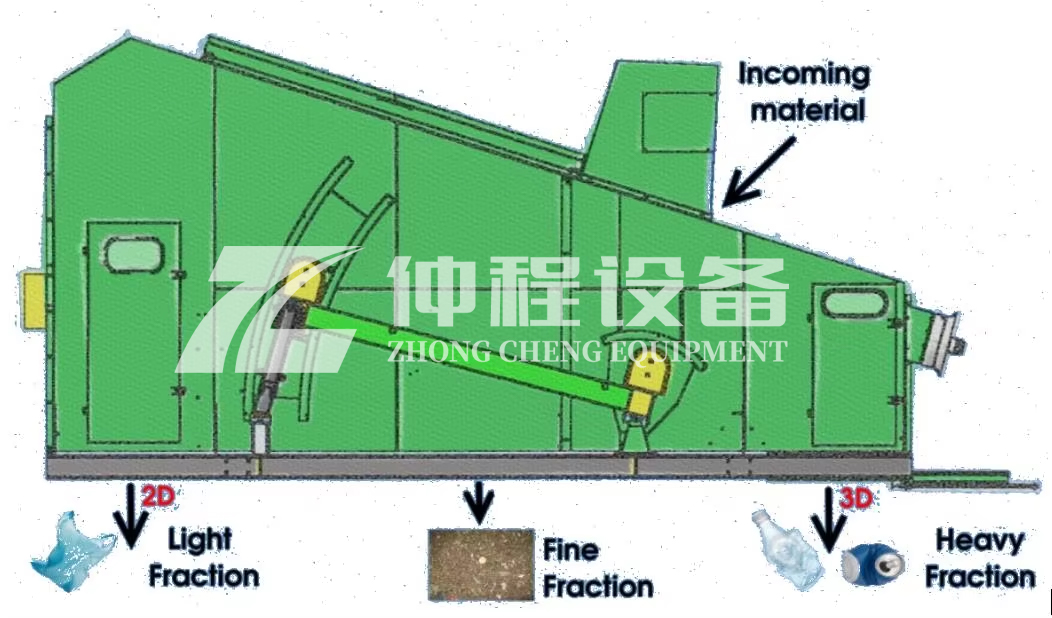

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...