The Role of Bag Openers in Waste Sorting

In the realm of waste management, the evolution of technology has played a pivotal role in enhancing efficiency and sustainability. One such innovation that stands out is the bag opener, a machine designed to automate the process of opening waste bags during the sorting phase. This device not only accelerates the sorting process but also ensures a more hygienic and safer working environment for personnel involved in waste management.

How Bag Openers Work

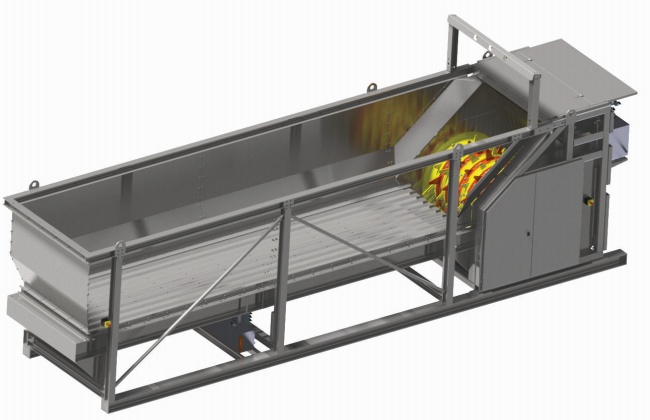

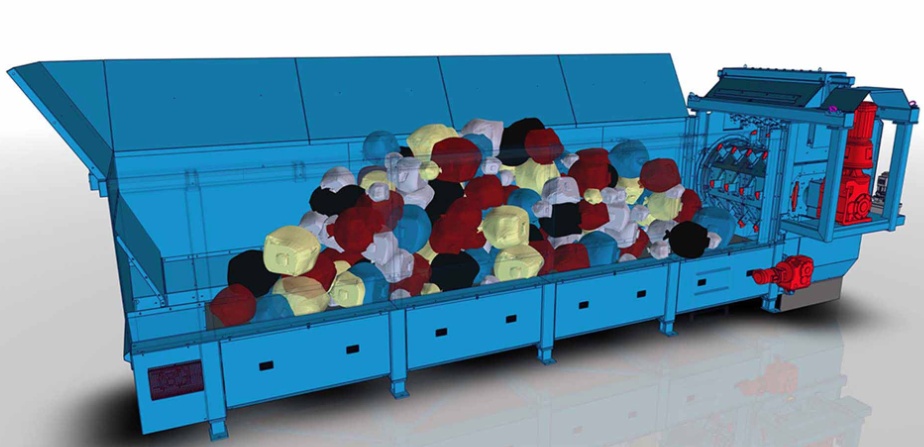

A bag opener, as the name suggests, is a mechanical device that automatically cuts open plastic or paper bags containing waste. These machines can be integrated into larger waste processing systems, where they serve as a critical first step in the sorting line. Typically, waste bags are fed into the machine, which then uses sharp blades or a similar mechanism to slice the bags open, allowing the contents to spill out onto a conveyor belt for further processing.

The design of these openers is sophisticated, with sensors and controls that ensure the bags are opened without causing damage to the contents or the machinery itself. Some advanced models even come equipped with systems to detect and remove hazardous materials before they enter the main sorting line, thereby protecting both the equipment and the workers.

Benefits of Using Bag Openers

1. Increased Efficiency: By automating the bag-opening process, waste facilities can handle a higher volume of waste in less time. This leads to a more streamlined operation and can significantly reduce labor costs.

2. Improved Safety: Manual handling of waste bags, especially those containing potentially hazardous materials, poses risks to workers' health and safety. Bag openers eliminate the need for direct human contact with waste, reducing the risk of injury and exposure to harmful substances.

3. Enhanced Hygiene: The automated process minimizes the spread of bacteria and other contaminants, contributing to a cleaner work environment.

4. Consistency and Reliability: Machines perform tasks uniformly and do not suffer from fatigue, ensuring consistent performance over long periods.

5. Data Collection: Advanced bag openers can be integrated with data collection systems, providing valuable insights into the types and volumes of waste being processed. This information can be used to optimize waste management strategies and support recycling initiatives.

Environmental Impact

The use of bag openers in waste sorting contributes positively to environmental conservation efforts. By improving the efficiency of the sorting process, these machines help to increase the recovery rate of recyclable materials, thereby reducing the amount of waste sent to landfills. Additionally, by facilitating the separation of hazardous materials, they play a crucial role in preventing contamination of the recycling stream and the environment.

The integration of bag openers into waste management processes represents a significant advancement in the field. Not only do they offer practical benefits such as increased efficiency and improved worker safety, but they also contribute to broader environmental goals by promoting better recycling practices. As technology continues to evolve, it is likely that we will see even more innovative solutions that further enhance the capabilities of waste management systems, making them more effective, sustainable, and environmentally friendly.

| BO12 | BO14 | BO16 | BO18 | |

| Width | 1200mm | 1400mm | 1600mm | 1800mm |

| Number of rotors | Two | Two | Two | Two |

| Speed of the main rotor | 0-25 rpm | 0-25 rpm | 0-25 rpm | 0-25 rpm |

| Speed of second rotor | 0-5 rpm | 0-5 rpm | 0-5 rpm | 0-5 rpm |

| Power | 15+5.5kw | 15+5.5kw | 15+7.5kw | 15+7.5kw |

| Throughput | 10-30m³/h | 20-50m³/h | 40-80m³/h | 60-100m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...