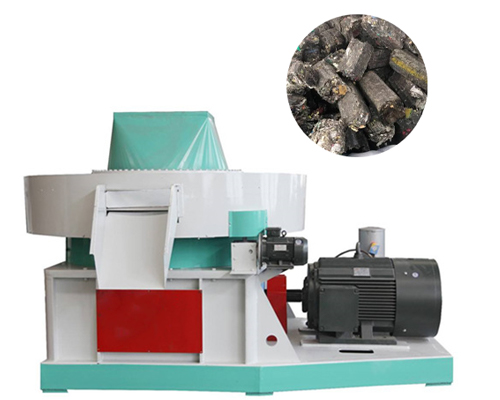

Automatic RDF Pellet Machine for Industrial Solid Waste Domestic Waste

1).Introduction:

RDF (Refuse Derived Fuel) Pellet Machine , its also called RDF Rod making Machine. It is a kind of equipment specially used to convert non-hazardous solid waste such as urban domestic waste and industrial waste into fuel rods. These fuel rods can be used as alternative fuels in cement kilns, power plants and other facilities to realize waste resource utilization, help reduce dependence on traditional fossil fuels, and reduce environmental pollution.

2). The working principle of RDF Pellet Machine is as follows:

Raw material preparation:

1. Collection and screening: Collect agricultural and forestry processing waste such as sawdust, straw, rice husks, bark, or combustible materials in domestic waste after crushing and sorting (such as plastic, fiber, rubber, wood, food waste, etc.).

2. Pretreatment: Pre-treat the collected raw materials, including crushing, drying and other operations, crush the raw materials to a suitable size (generally less than 50mm), and control their moisture content within a certain range (usually 10%-25%).

3. Feeding process: The pretreated raw materials are transported to the feed port of the rod making machine through feeding conveyors and other devices.

3). Extrusion molding:

1. Mechanical structure function: In the compressor of the rod making machine, there are key components such as the pressure roller and the ring die. The motor drives the main shaft to rotate, and then drives the pressure roller to rotate.

2. Forming pressure: The rotating pressure roller and the ring die cooperate with each other to apply pressure to the incoming raw materials. Under the extrusion of the pressure roller, the raw materials are continuously pushed to the forming hole on the ring die.

3. Extrusion molding: Under the strong pressure, the raw materials are forced to be extruded from the forming hole of the ring die to form a rod-shaped solid particle fuel with a cross-sectional size of 33-40mm and a length greater than 150mm.

4. Discharging and subsequent processing: The formed rod-shaped fuel falls from the discharge port, and after subsequent processing such as cooling (to further reduce the moisture content and stabilize it in a suitable range, generally not more than 14%), it can be bagged and packaged for storage and transportation.

4).In short, the RDF Pellet Machine converts loose raw materials into high-density rod-shaped solid fuel through a series of mechanical actions and physical processes. This fuel has the advantages of high calorific value, small volume, easy storage and transportation, and can be widely used in heating, domestic stoves, boilers, biomass power plants and other fields.

5).Parameter:

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-07-16Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...

-

2024-04-13Wobbler FeederWobbler feeder is a type of feeding equipment that uses rotating elliptical bars, known as wobblers, to separate materials based on size and type before they re...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...