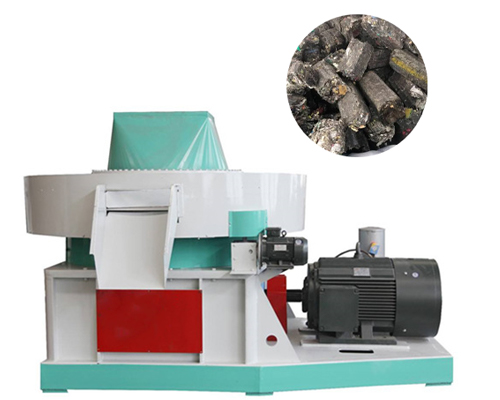

Equipment for Processing Fuel into Rods-RDF Rod Making Machine

1). Definition

RDF rod making machine is a device that processes refuse-derived fuel (RDF) into rod-shaped fuel. RDF is mainly obtained from solid waste such as municipal solid waste and industrial waste through a series of treatments such as screening, crushing, drying and compression. The function of RDF rod making machine is to further process and shape these pre-treated RDF materials into rod-shaped fuel that is easy to store, transport and use.

2). Working principle

1. First, the pre-treated RDF raw materials are transported to the working chamber of the rod making machine through the feeding device. In the working chamber, there is a screw extrusion device. The screw rotates under the drive of the motor, pushing the raw materials forward and extruding them. As the raw materials are continuously extruded, the internal gaps gradually decrease and the density increases. Under the continuous extrusion of the screw, the raw materials are extruded into rods through the outlet of the forming die. The shape and size of the forming die determine the shape and size of the rod-shaped fuel, which can generally be replaced according to actual needs.

3). Main structural components

1. Feeding system: Its function is to evenly transport the RDF raw materials into the rod making machine. This system usually includes a feeding hopper and a feeding screw. The feeding hopper is used to store the raw materials. The feeding screw can control the feeding speed of the raw materials to ensure a stable feeding amount and avoid affecting the quality of the rods due to too fast or too slow feeding.

2. Extrusion system: This is the core part of the RDF rod making machine, mainly composed of a screw and an extrusion barrel. The screw is generally spiral-shaped, and the extrusion force generated by rotation compacts the raw materials and pushes them forward. The extrusion barrel is a cylindrical structure surrounding the screw, which provides support and guidance for the extrusion of the raw materials, and also bears the pressure during the extrusion process.

3. Heating system: In some RDF rod making machines, a heating system is equipped to make the raw materials better shaped. The heating system can properly heat the raw materials, reduce the viscosity of the raw materials, and make them easier to be extruded into rods. The heating temperature can usually be adjusted according to the characteristics of the raw materials, generally within a certain temperature range, to avoid the raw materials from being damaged by overheating.

4. Molding system: mainly the molding die, located at the exit of the rod making machine. The shape of the internal channel of the mold determines the shape of the rod fuel, such as round, square, etc. The material of the mold is usually high-strength alloy steel to withstand the high pressure during the extrusion process, and has good wear resistance to ensure long-term use.

5. Power system: Provide power for various components of the rod making machine, mainly including motors and transmission devices. The motor provides rotational power and transmits power to power-requiring components such as screws through transmission devices such as belts, chains or gears, so that the entire rod making machine can operate normally.

4). Application field

1. Energy field: RDF rod fuel can be used as an alternative fuel for power generation, heating, etc. In some small biomass power plants or industrial boilers, RDF rod fuel can partially replace traditional fossil fuels such as coal, reduce energy costs and reduce pollution to the environment. For example, some cement plants' rotary kilns can use RDF rod fuel during the combustion process, and use the heat generated by its combustion to dry raw materials or provide part of the heat energy in the production process.

2. Waste treatment field: It helps to solve the problem of landfill space shortage. By making garbage into RDF rod fuel, not only can the volume of garbage be reduced, but also the garbage can be converted into valuable energy products, realizing the resource utilization of garbage. For example, in the garbage treatment centers of some large cities, RDF rod making machines can process a large amount of domestic garbage and convert it into fuel for subsequent use.

5). Parameter

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...