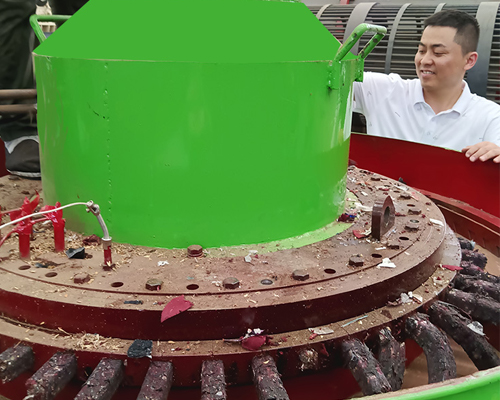

Hot Sale Refuse-Derived Fuel(RDF) Pelletizing Machine

1). Product Description:

1.Refuse-Derived Fuel(RDF) Pelletizing Machine is characterized by high calorific value, stable combustion, easy transportation, easy storage, low secondary and low emission of dioxin-like substances, widely used in drying engineering, cement manufacturing, heating engineering, and power generation engineering, and other fields.

2.Refuse-derived fuel (RDF) Pelletizing Machinetechnology is to remove non-combustible materials such as metal, glass, and sand from garbage by crushing and drying the separating garbage such as domestic and industrials garbage, after crushing and drying the combustible materials (such as plastic, fiber, rubber, wood, food waste, etc.) in the garbage, additives are added and then the solid fuel is made.

2). Working principle:

1.The preparation process of domestic waste(RDF) derived fuel production line generally includes four steps: Coarse crushing ,Sorting,Fine crushing,Drying and molding.

2.The refuse is first crushed by a coarse crusher, and then incombustible is separated from the combustible by sorting equipment such as magnetic separation, butterfly screen, drum screen, spring screen, and air separator, and air separator, and the combustible goes into a fine crusher for secondary crushing, after the broken material into the dryer, the moisture will be up to 10%, after drying fuel into the high-pressure molding machine compression molding.

3).Raw material:

1. Corn stalks, wheat straw, cotton stalks, rice husks, peanut shells, corn cobs, branches, Agricultural and forestry waste such as leaves, wood chips, animal manure;

2. Solid waste, paper mill waste, garment factory scraps, used clothes, domestic garbage, industrial waste, industrial sludge, car interior trim scraps, shoe factory, luggage factory scraps, etc.;

3.The above raw materials are crushed and processed into rods to form combustion rods (RDF), which are used in power plants and cement. It is used as fuel for large boilers such as factories.

4).Application:

1. Widely used in domestic stoves, heating stoves, hot water boilers, drying furnaces;

2. Biomass gasifiers and biogas fermentation. Use raw materials.

3. For civilian cooking and heating;

4. Drying grain, wood, fruits, fried tea, etc.; district heating; Produces electricity; businesses use hot water and steam.

5). Technical parameters:

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...