Bouncing Screen Technology Revolutionizes Waste Management

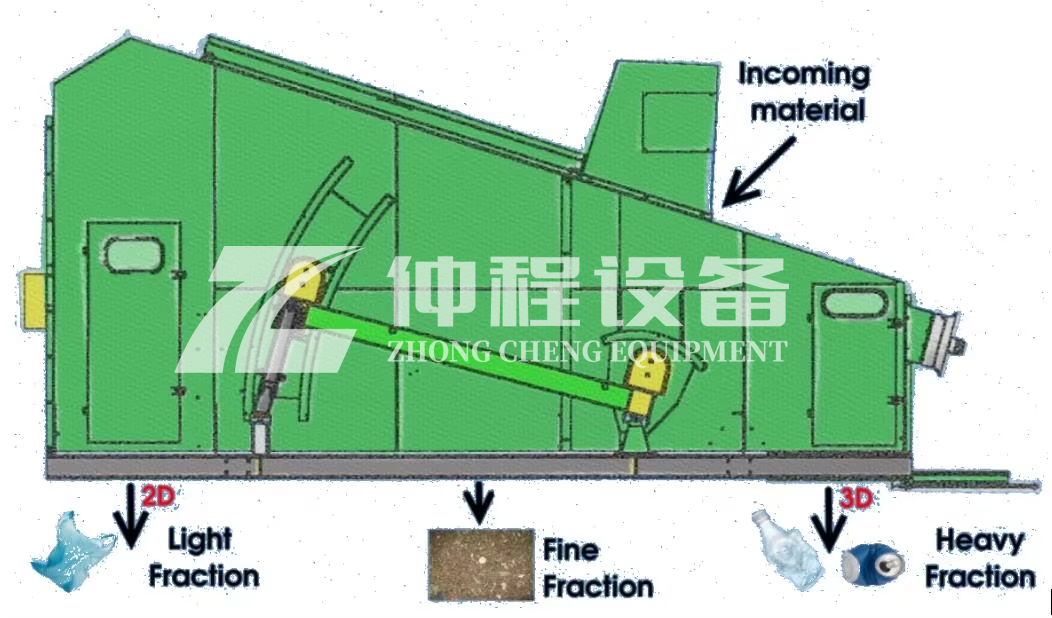

Bounce sorting screen is a device that sorts materials based on the size, density, and shape of different components. It is an ideal equipment for processing and sorting household waste, stale waste,decoration waste,industrial waste, paper recycling, and other industries. Bounce sorting screen drives the screen plate up and down to move back and forth through an eccentric shaft, causing the household waste on the screen plate to be shaken and scattered into heavy,rolling 3D material parts (such as plastic bottles, wood, cans, etc.), light, flat 2D material parts (film, paper, cardboard, old clothes), and undersized material parts (sand, food residue), which facilitates the subsequent processing.

he bouncing screen, also known as a vibrating screen or jigger, operates on the principle of vibration to separate materials based on their size. The screen is set into motion using mechanical or electromagnetic vibrators, causing the material placed on the screen to bounce and move forward. As the material bounces, smaller particles fall through the screen openings while larger particles remain on top, effectively sorting the material.

Application Industries

Bouncing screens are widely used in various industries for the purpose of screening and grading materials:

- Mining and Minerals: For sorting different sizes of minerals and ores.

- Construction Materials: Sorting sand, gravel, and crushed stone.

- Recycling: Separating recyclable materials like plastics, metals, and paper.

- Agriculture: Grading seeds, grains, and other agricultural products.

- Chemical Industry: Screening powders and granules for quality control.

Food Processing: Sorting and grading food products such as nuts, fruits, and vegetables.

Advantages

- High Efficiency: Bouncing screens can process large volumes of material quickly and efficiently, making them suitable for high-throughput operations.

- Versatility: They can handle a wide range of materials and particle sizes, making them adaptable to different applications.

- Low Maintenance: Designed for durability and ease of maintenance, reducing downtime and operational costs.

- Customizable: Screens can be customized with different mesh sizes and shapes to meet specific sorting requirements.

- Energy Efficient: Modern bouncing screens are designed to use less energy compared to older models, contributing to cost savings and environmental sustainability.

Reliability: With robust construction and reliable operation, bouncing screens provide consistent performance over long periods.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.