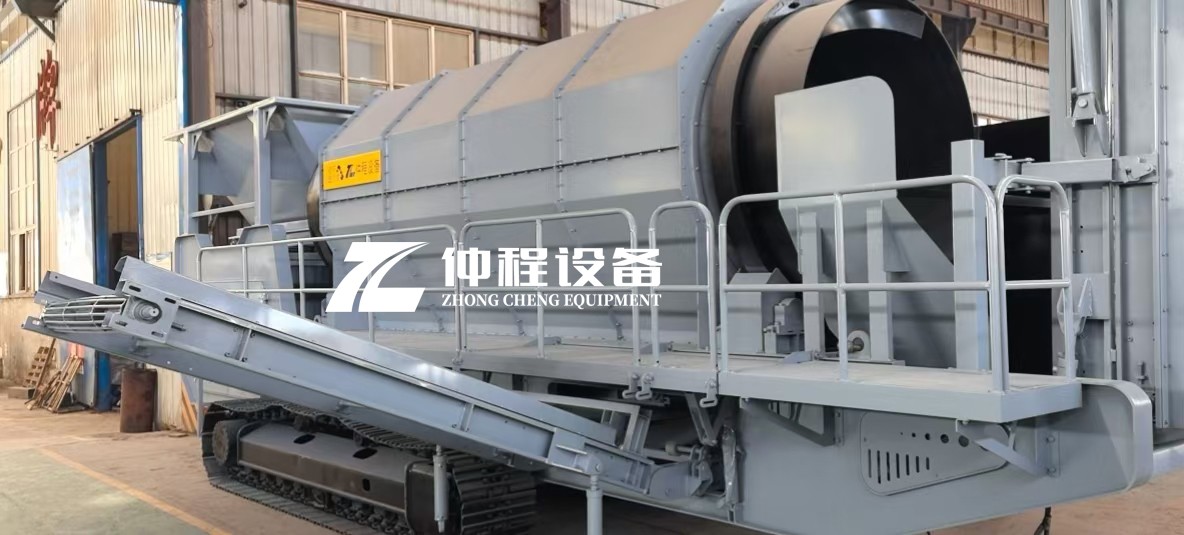

Mobile Drum Screens in Waste Management: Efficiency and Versatility

About the mobile drum screens

Mobile drum screens are versatile pieces of equipment that find extensive use in various industries, particularly in waste management. Here are some key applications:

1. Construction and Demolition (C&D) Waste:

- Material Separation: Mobile drum screens are used to separate different types of debris, such as concrete, bricks, wood, and metal, from finer materials like soil and dust. This separation is crucial for recycling and reusing materials, reducing the amount of waste sent to landfills.

- On-Site Processing: The portability of these screens allows for on-site processing, which can significantly reduce transportation costs and environmental impact.

2. Municipal Solid Waste (MSW):

- Preliminary Sorting: In MSW facilities, mobile drum screens are often the first step in the waste processing line. They help separate organic waste, paper, plastics, and other recyclables from non-recyclable materials.

- Volume Reduction: By removing smaller particles, these screens can reduce the volume of waste, making subsequent processing steps more efficient.

3. Composting:

- Material Preparation: Before composting, it is essential to remove oversized materials and contaminants. Mobile drum screens ensure that only the appropriate materials enter the composting process, leading to higher-quality compost.

- Screening Compost: After the composting process, these screens can be used to remove any remaining large particles, ensuring a uniform final product.

4. Biomass Processing:

- Fuel Preparation: In the production of biomass fuels, mobile drum screens help remove contaminants and ensure that the fuel meets specific size and quality requirements.

- Material Handling: They can also be used to separate different types of biomass materials, such as wood chips, straw, and agricultural residues.

Advantages of Using Mobile Drum Screens

1. Portability:

- On-Site Processing: The mobility of these screens allows them to be deployed directly at the waste generation site, reducing the need for transportation and minimizing associated costs and environmental impacts.

- Flexibility: They can be easily moved to different locations, making them ideal for temporary or project-based operations.

2. Efficiency:

- High Throughput: Mobile drum screens are designed to process large volumes of waste quickly and efficiently, reducing the time and labor required for waste management.

- Continuous Operation: Many models are capable of continuous operation, ensuring a steady flow of processed materials.

3. Versatility:

- Multiple Materials: These screens can handle a wide range of materials, from fine particles to larger objects, making them suitable for various applications.

- Adjustable Settings: The drum speed and hole sizes can be adjusted to suit different materials and desired outcomes, enhancing their adaptability.

4. Cost-Effectiveness:

- Reduced Transportation Costs: By processing waste on-site, the need for long-distance transportation is minimized, leading to cost savings.

- Lower Operational Costs: Efficient processing reduces the need for additional equipment and labor, lowering overall operational expenses.

5. Environmental Benefits:

- Recycling and Reuse: Effective waste separation facilitates higher recycling rates, reducing the amount of waste sent to landfills and conserving resources.

- Reduced Contamination: By removing contaminants and oversized materials, mobile drum screens improve the quality of recycled materials and the effectiveness of subsequent processing steps.

Why Use Mobile Drum Screens for Waste Screening?

1. Enhanced Recycling Rates:

- Material Recovery: Mobile drum screens help recover valuable materials from waste streams, increasing recycling rates and reducing resource depletion.

- Quality Control: By ensuring that only appropriate materials are processed, these screens improve the quality of recycled products, making them more marketable.

2. Operational Efficiency:

- Time Savings: Quick and efficient processing reduces the time required for waste management, allowing operations to run more smoothly.

- Labor Reduction: Automated screening processes require fewer personnel, reducing labor costs and improving safety.

3. Sustainability:

- Environmental Impact: By promoting recycling and reducing landfill use, mobile drum screens contribute to more sustainable waste management practices.

- Energy Efficiency: Efficient processing and reduced transportation needs lead to lower energy consumption and a smaller carbon footprint.

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

mobile drum screens offer a range of benefits that make them an essential tool in modern waste management. Their portability, efficiency, and versatility make them ideal for various applications, from construction sites to municipal waste facilities. By using mobile drum screens, waste management operations can become more efficient, cost-effective, and environmentally friendly.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management