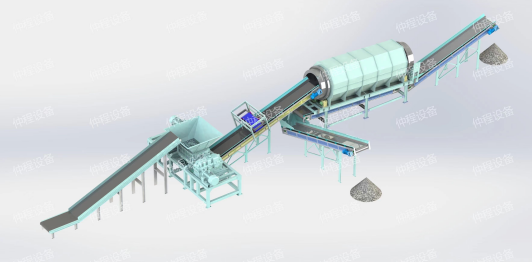

Rotary Trommel screen

Use of Tromel Rotary Drum Screen in Solid Waste and Compost Processes

Trommel screen is an effective trommel screen system that separates materials

according to their size in waste management and recycling processes.

Rotary drum screen offers high efficiency especially in the processing of solid

waste, compost, soil, organic waste and various minerals. Trommel screen stands

out as a powerful machine used in industrial areas such as recycling, mining,

agriculture and construction. Drum screen separates materials quickly and effectively

according to their size thanks to the perforated structure inside the rotating drum.

While large parts are directed to the exit section of the drum, small parts are

separated by passing through the holes inside the drum.

Trommel screen is an ideal choice for processes such as separation of plastic, wood,

metal and construction waste in recycling facilities. Thanks to the trommel screen,

large volumes of waste are classified more easily and the efficiency of recycling processes

is increased. The rotary drum screen reduces operating costs with its energy

efficient motors and durable structure, while supporting environmental sustainability.

In addition, the drum screen offers a long-lasting solution to industrial enterprises with

its user-friendly design and ease of maintenance. The drum screen, which can process

different types of waste quickly and efficiently, accelerates the separation of waste and

optimizes recycling processes. The rotary disc screen provides great advantages to

enterprises in waste management, both environmentally and economically. The tromel screen,

which offers a competitive solution in terms of rotary screen prices, increases efficiency

in recycling processes. Drum screen construction contributes to an environmentally friendly

and sustainable recycling process by providing a cost advantage with the high performance

it provides in recycling and waste management processes.

Rotary Trommels are designed to efficiently separate and size recyclable material

that is prone to sticking or jamming in other secondary separation technology.

Heavy-duty drive systems and trommel bodies are easy to clean and easy to maintain.

Super-duty trommel designs impart greater impact force to the product and are optimized

for materials such as glass recovery and shingle processing.

FEATURES:

Material infeed can be through either a bag opener for municipal waste or

to a bypass feeder for C&D and other non-bagged materials.

Separation is achieved using our Vibratory Screen for initial separation, a

vibratory fines screen, and through the use of our Air Density Separator.

Ferrous separation is also available .

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

For more information on rotary trommels, contact us.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2023-01-12Conveyor BeltGarbage conveyor/Trash conveyor belt system is a processing line to classify paper, plastic, metal, glass, and organic matter and realize the recycling of rubb...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...