Compaction baler: the core equipment of efficient waste management

Introduction

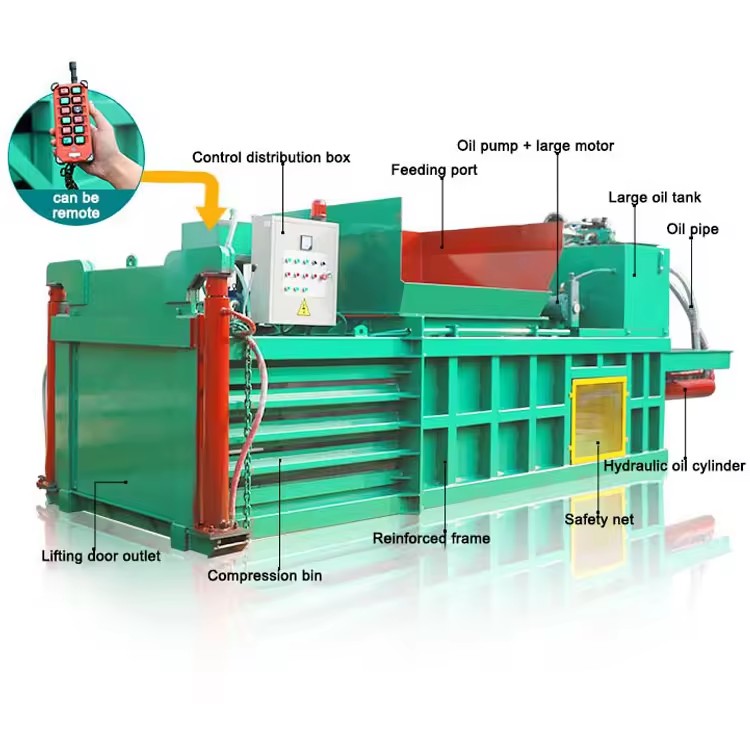

A compactor, also known as a trash compactor or waste compactor, is a machine or mechanism used to reduce the size of waste material or recyclable material through compaction. This process makes it easier to handle, transport, and dispose of waste by significantly reducing its volume.

Working Principle

The working principle of a compactor generally involves compressing waste materials into a much smaller volume using hydraulic pressure. The main components of a compactor include a powerful hydraulic system, a compression chamber, and a pusher plate. Waste materials are loaded into the compaction chamber, where the hydraulic system drives the pusher plate to apply high pressure, thereby compacting the waste into a dense block. Once the cycle is complete, the compacted waste can be ejected for disposal or recycling.

Applications

Compactors find widespread applications in various industries and settings, including:

- Municipal Solid Waste Management: Used by cities and municipalities for efficient waste collection and landfill management.

- Recycling Facilities: Facilitates the processing of recyclables like paper, cardboard, plastics, and metals.

- Industrial Manufacturing: Helps in managing industrial waste, reducing disposal costs, and improving space utilization.

- Retail and Commercial Sectors: Enables businesses to manage their waste efficiently, especially in sectors that generate large volumes of packaging waste.

Construction Sites: Aids in handling construction debris and demolition waste.

Advantages

- Space Saving: By reducing the volume of waste, compactors help save valuable storage and transportation space.

- Cost Reduction: Lower transportation costs due to fewer trips required for waste removal, leading to cost savings.

- Environmental Benefits: Encourages recycling and reduces the amount of waste sent to landfills, contributing positively to environmental sustainability.

- Health and Safety: Reduces the risk of pests and odors associated with loose waste, promoting better hygiene.

Efficiency Improvement: Streamlines the waste management process, making it more efficient and manageable.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...