High Sorting Efficiency Garbage Separator - Air Drum Separator

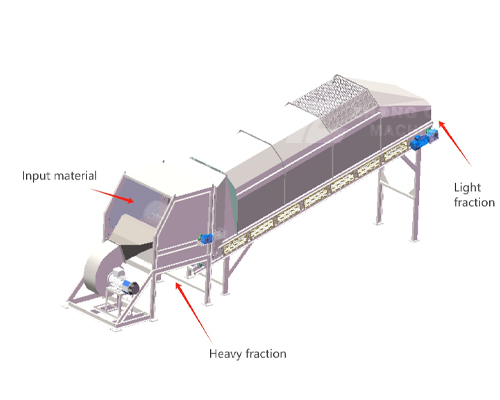

Industrial Air drum separator is a kind of sorting equipment used in industrial production process.

1). Basic definition

1. It is mainly a machine that uses the difference of aerodynamic properties such as suspension speed of materials and impurities (or different materials) in air flow to separate light and heavy materials in mixed materials. Simply put, it is to select material components that meet specific requirements by controlling air flow.

2). Equipment structure

1. Sorting chamber structure

The shape and internal structure of the sorting chamber have an important influence on the sorting effect. If the shape of the sorting chamber is unreasonable, it may cause uneven air flow distribution. For example, a rectangular sorting chamber may have air flow dead corners at the corners, so that some materials cannot get full air flow effect.

The internal guide device is also critical. Reasonable guide devices can guide the air flow to flow in the ideal direction, so that the material moves regularly in the sorting chamber. Without guide devices or poorly designed guide devices, the air flow may produce unstable flow such as vortex, which affects the normal sorting of materials.

2. Feeding and discharging methods

The position of the feed port and the feeding method should ensure that the material can be evenly distributed in the air flow of the sorting chamber. If the feed port is not properly positioned, such as being close to the light material outlet, some materials may be discharged directly before they are fully sorted, affecting the sorting effect.

The design of the outlet is also very important. The size and position of the light and heavy material outlets should be determined according to the material flow and movement trajectory. If the outlet size is not appropriate, the material may be blocked or the discharge may be poor, affecting the continuity and stability of the entire Air drum separator process.

3). Details related to the working principle

1. When the material enters the Air drum separator, under the action of the airflow, the lighter material will be carried up or blown to a farther place by the airflow, while the heavier material will sink or fall to a closer place due to gravity. For example, when recycling a mixture of plastics and metals, plastics are generally lighter and will be carried away by the airflow, while metals are heavier and will sink, thereby separating the two.

2. The generation of airflow usually relies on a fan, and the high-speed airflow generated by the fan forms a stable flow field inside the Air drum separator. The speed, direction and other parameters of this flow field can be adjusted according to the characteristics of the material to achieve the best sorting effect.

4). Application scenario description

1. In the waste treatment industry, industrial air separators can be used to sort recyclables from domestic waste. For example, the separation of light materials such as paper and plastic film from heavy materials such as bricks, tiles, and glass is helpful for subsequent recycling and reuse.

2. In the mining industry, it is used in the mineral processing process. It can separate the gangue (generally lighter) and useful ore (relatively heavier) in the ore, or separate minerals of different densities, improve the grade of the ore, and reduce the workload of subsequent processing.

3. In the grain processing industry, it is used to remove impurities in grains, such as dust, empty grains (lighter) and full grains (heavier) to ensure the quality of grains.

5). Model

| Air drum separator 800 | Air drum separator 1200 | Air drum separator 1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...

-

2024-07-10msw trommel screen for waste recycling machineThis equipment is suitable for the particle classification process in all walks of life:The equipment is simple, easy to operate,and can be operated with a larg...

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.