Hydraulic baler overview, working principle, advantages and application industries

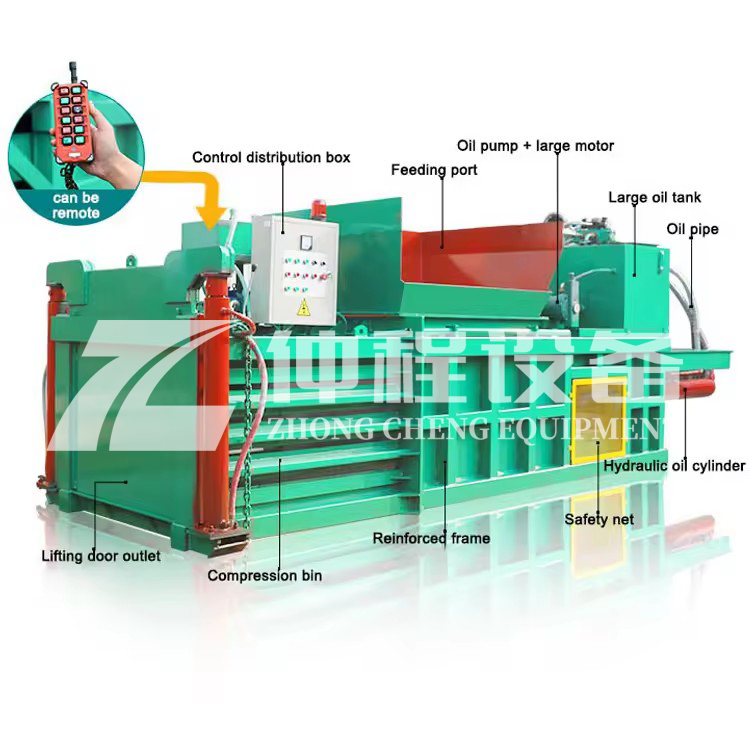

A Hydraulic Baling Press is a type of machinery that utilizes hydraulic power – the force exerted by a liquid under pressure – to compress loose materials into compact bales or bundles. It finds extensive application across various industries for material handling and recycling processes.

Working Principle

The operation of a hydraulic baling press is based on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. When hydraulic oil is pumped into the hydraulic cylinder, it drives the piston to move, generating significant compressive force. This force is then transferred through a pressing plate onto the material to be compressed, squeezing it into a more condensed shape. Once the compression cycle is complete, the hydraulic oil is withdrawn, allowing the pressing plate to return to its initial position, ready for the next batch of material.

Advantages

- High Efficiency: A hydraulic baling press can process large volumes of material within a short time frame.

- Space Saving: The reduced volume of compressed material facilitates easier storage and transportation.

- Cost Reduction in Transportation: Smaller material volumes mean fewer transportation resources are required to move the same quantity of material.

- Enhanced Recycling Efficiency: For recyclable materials such as metals, plastics, and paper, compression makes them easier to handle and reuse.

- High Degree of Automation: Modern hydraulic baling presses often come with automated control systems, enabling continuous operation and boosting productivity.

Safety: Hydraulic systems are relatively stable, reducing the risk of mechanical failures. Many machines also feature safety guard mechanisms.

Application Industries

- Waste Management and Recycling Industry

- Paper and Cardboard Processing Industry

- Metal Recycling Industry

- Plastic Recycling Industry

- Agriculture and Forestry Products Processing Industry

- Textile and Garment Industry

- Food Processing Industry

Packaging Industry

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2023-01-12Disc ScreenDisc screen, also known as a disc scalping screen, is a mechanical device used to separate materials based on size. It is commonly used in industries such as wa...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-05-29Landfill stale garbage screening projectAfter communicating with our domestic customers in Shandong Province, we learned that he needed to dispose of the garbage in the landfill through excavation, sc...

-

2024-06-08Solutions for Jaw Crusher ProblemsJaw crusher is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive stren...