Waste Tire Recycling

Tyre recycling solutions

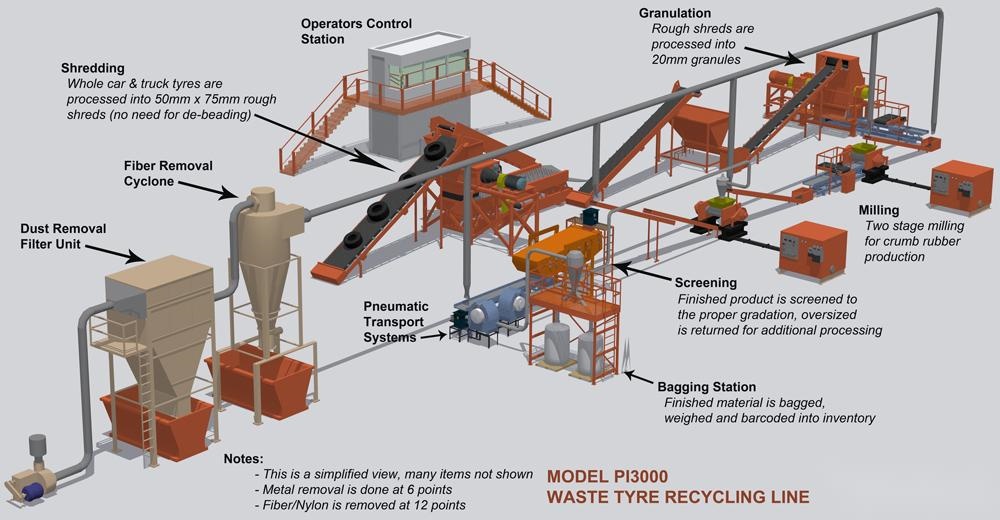

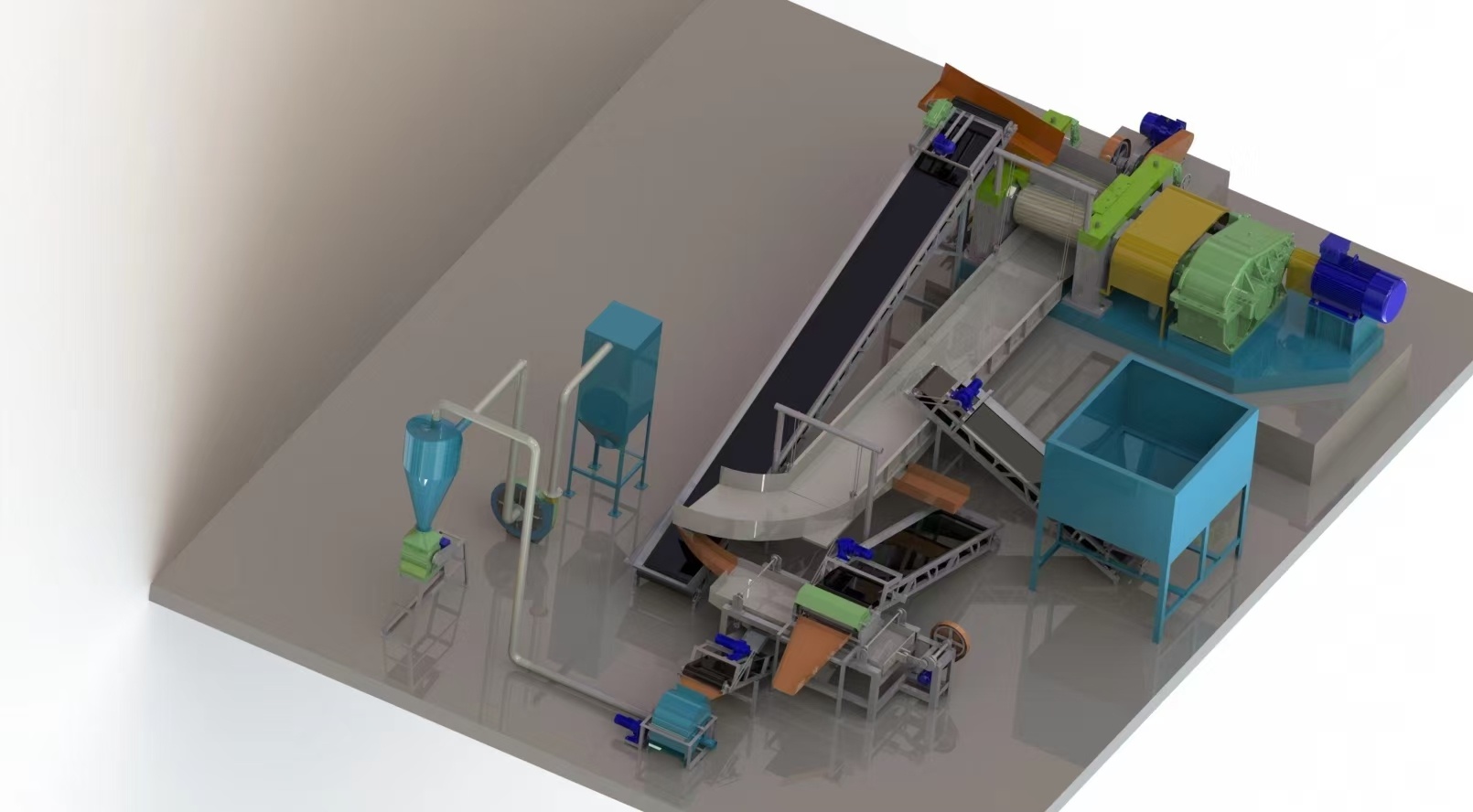

We offer both standard and customized tyre recycling solutions depending on your requirements for input tyre type, production capacity, and output size/purity. The standard solutions for tyre recycling have capacities ranging from 500 – 20.000 kg input/production hour depending on your needs. These are typically the starting point when customizing solutions e.g. for larger capacities.

The systems and machines are developed based on ambient mechanical technique for size reduction and separation. No melting or chemical treatment required.

Scrap Tire Processing

With the ever increasing health and environmental concerns, the disposal of scrap tires is a growing problem all over the world. A scrap tire processing plant recycles whole car and truck tires into a valuable product called crumb rubber. This crumb rubber can then used in numerous applications including sport fields, rubberized asphalt for paving and a wide variety of molded products. The steel and fiber removed during this process is also recycled into various products.

Main machine

Tire single shaft shredder

Separate Sieves, Can Be Replaced Independently. Specific Sieve Aperture To Ensure Discharging Size.Rotor Blades Are Made Of High Wear-Resistant And Corrosion-Resistant Alloy, Long Service, Repairableand Easy To Replace.Installing Shock Absorbers To Make Them Shred Smoothly.Push Box Is Made Of Brass, Wear-Resistant, Can Be Replaced And Adjusted, Ensuring Pushing Speed Is Constant And The Shredding Box Is Sealed

Tire double shaft shredders

Driven By Motor And Reducer, High Transfer Power And Operate Steadily. PLC Control System Is Equipped With Siemens LCD Screen; Real Time Monitoring, Abnormal Alarm,Remote Diagnosis, Data Analysis, Intelligent Operation And Maintenance. Rotor Blades Is Made Of High Wear-Resistant And Corrosion-Resistant Alloy, Long Service, Repairable And Easy To Replace.4 Layers Bearing Seal, Waterproof, Dustproof.

Single shaft shredder solution

The Shredder’s Blades Are Mounted On The Knife Holder With Screws, Making Them Easy To Detach And Replace. Each Blade Can Be Used On Four Sides, Maximizing The Lifespan Of The Blades And Minimizing Maintenance Downtime. The Straightforward Design Facilitates Quick And Easy Blade Changes, Ensuring Continuous And Efficient Operation.

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Motor(kw) | 11*2 | 18.5*2 | 35*2 | 45*2 | 55*2 | 75*2 | 110*2 |

Reducer | P6-P7 | P7-P8 | P8-P10 | P10-P12 | P11-P13 | P12-P16 | P14-P16 |

| Siemens or other motors, planetary reducers or other reducers can be customized according to customer requirements | |||||||

| Rotation Speed | 8-20rmp | 8-20rmp | 8-15rmp | 8-15rmp | 8-15rmp | 8-12rmp | 8-12rmp |

| Blades Diameter | 220-320 | 260-320 | 260-400 | 400-500 | 400-500 | 500 | 500 |

| Blades material | The material of the blades (55sicr, 5crsi, 9crsi, skd11, m6v, h13) can be customizedaccording to the customer's actual usage | ||||||

| Feeding Size | 1200*900mm | 1400*1000mm | 1600*1200mm | 1800*1300mm | 2000*1300mm | 2200*1700mm | 2400*2000mm |

| The size and appearance of the feeding hopper can be customized according to thecustomer's feeding situation | |||||||

| Weight(kg) | 1800 | 2500 | 3700 | 5500 | 7500 | 9500 | 13000 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.

-

2024-06-05Waste Trommel And Copmost TrommelHowever, it's important to choose the right type of drum screen based on your specific needs. Today, Kevin from Zhongcheng Company will explain the differences...

-

2024-05-18Hydraulic Cone CrusherHydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine cru...

-

2024-06-09Drum Screen RecyclingDrum screen machines are primarily used for material screening, helping to sort and recycle municipal solid waste and screen landfill waste. Their efficiency an...