Ballistic Separator: An Overview of Its Functionality and Applications

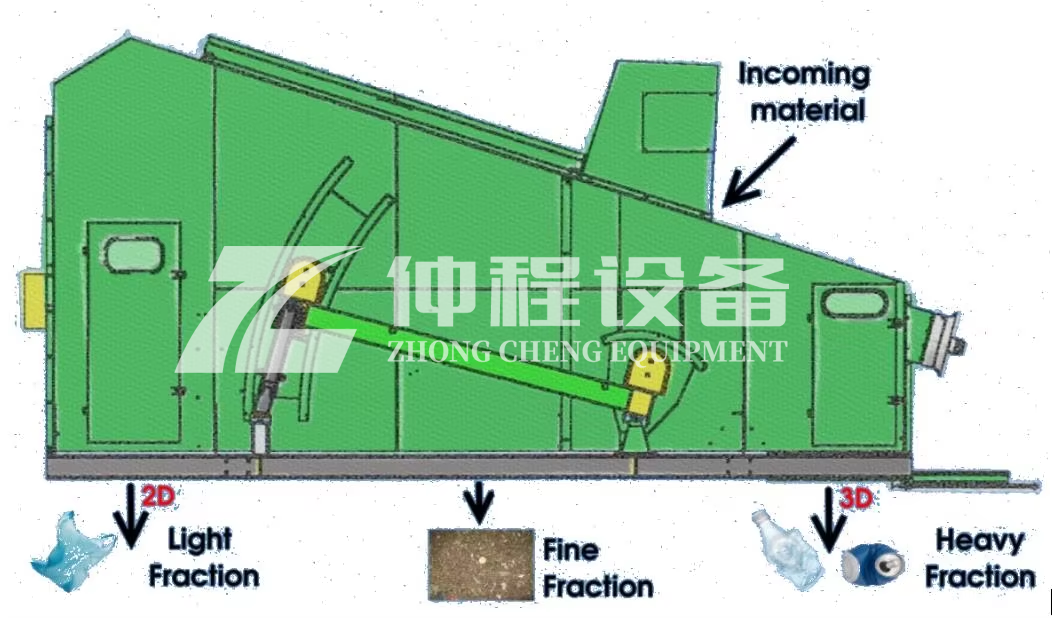

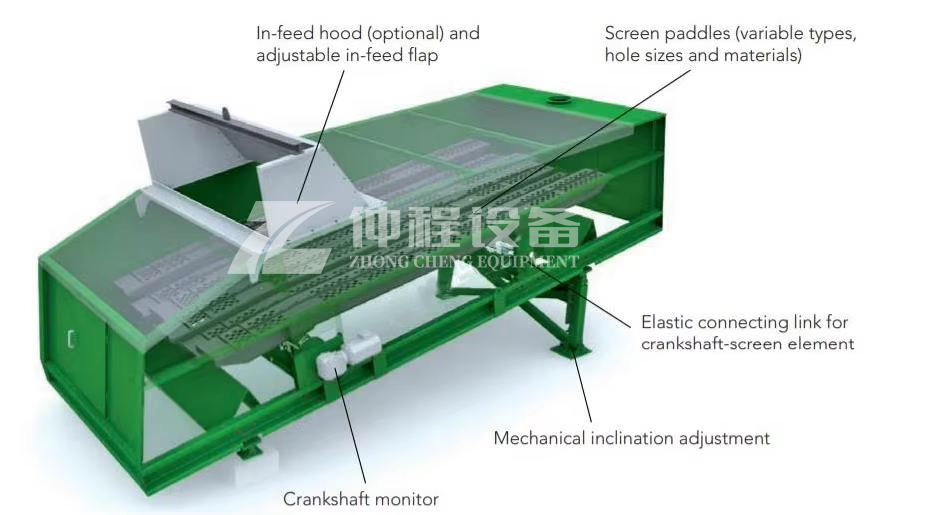

Working Principle

The ballistic separator operates on the principle of material separation through vibration and vertical movement. The screen is typically installed at a slight incline, and it uses an exciter or a similar mechanism to generate vibrations. As the material moves along the screen surface due to these vibrations, smaller particles pass through the screen mesh while larger particles are conveyed towards the discharge end. The vertical component of the motion helps to keep the material layer thin and ensures good contact between the material and the screen surface, enhancing the screening efficiency.

Applicable Industries

Bouncing screens can be used in various industries where efficient and gentle material handling is required. Some of the industries where they find application include:

- Agriculture: For cleaning seeds, grains, and cereals.

- Food Processing: To sort fruits, vegetables, or nuts.

- Pharmaceuticals: For grading powders and granules.

- Chemical Processing: To separate solid materials from liquids or for dry screening of various chemicals.

- Mining and Minerals: For sorting and grading coal, ores, and other mined materials.

Recycling: For separating recyclable materials such as plastics, paper, and metals.

Advantages

The advantages of using a bouncing screen include:

- Efficiency: They can process large volumes of material quickly and effectively.

- Versatility: Suitable for a wide range of particle sizes and materials.

- Reduced Wear: The design often results in less wear and tear compared to some other types of sieves, leading to lower maintenance costs.

- Gentle Handling: The vertical movement helps in handling fragile materials without causing significant damage.

- Ease of Maintenance: Many models are designed for easy access to the screen mesh for cleaning or replacement.

Energy Efficiency: Some designs consume less energy compared to conventional vibrating screens due to their operational mechanics.

Main Functions

Material Separation:

- The primary role of a bouncing screen is to separate mixed materials based on size. Smaller particles fall through the screen mesh, while larger particles are conveyed over the top and discharged separately.

Grading:

- Bouncing screens are used to grade materials into different size fractions. This is particularly useful in industries like mining, where ore needs to be sorted according to particle size before further processing.

Cleaning:

- In agriculture and food processing, these screens help clean harvested products by removing debris, stones, and other foreign materials that do not belong in the final product.

Dewatering:

- In processes where materials are washed or soaked, the bouncing screen can be used to remove excess water or liquid from the materials, aiding in dewatering processes.

Deagglomeration:

- When materials tend to clump together, the bouncing screen's action can help break up these agglomerates, ensuring better flow and more accurate sizing.

Quality Control:

- By removing undersized or oversized particles, the bouncing screen ensures that only the desired particle size reaches the customer or the next stage of processing, thus contributing to quality control.

Consistency:

Ensuring that all processed material meets a consistent size requirement is critical in many industries. Bouncing screens help maintain this consistency, which is vital for processes that rely on uniform particle sizes.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-20Mobile Impact Crusher PlantThe mobile impact crusher plant is a kind of crushing equipment based on a mobile platform. It uses an impact crusher as the host machine and is usually equippe...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2024-07-12Crush to Create: The Ultimate Eco-Friendly Plastic Shredder RevolutionThe working principle of a plastic shredder is mainly to tear large plastic materials into small pieces or fragments through mechanical force, in order to facil...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...