Bouncing Screens: The Efficient Solution for Material Separation in Various Industries

Date:2024-11-12

View: Point

Bouncing screens, also known as jumping screens or vibrating screens, are mechanical devices used in various industries for the purpose of separating materials based on size. These screens are commonly utilized in mining, construction, agriculture, and recycling industries to sort different sizes of particles or objects.

How They Work:

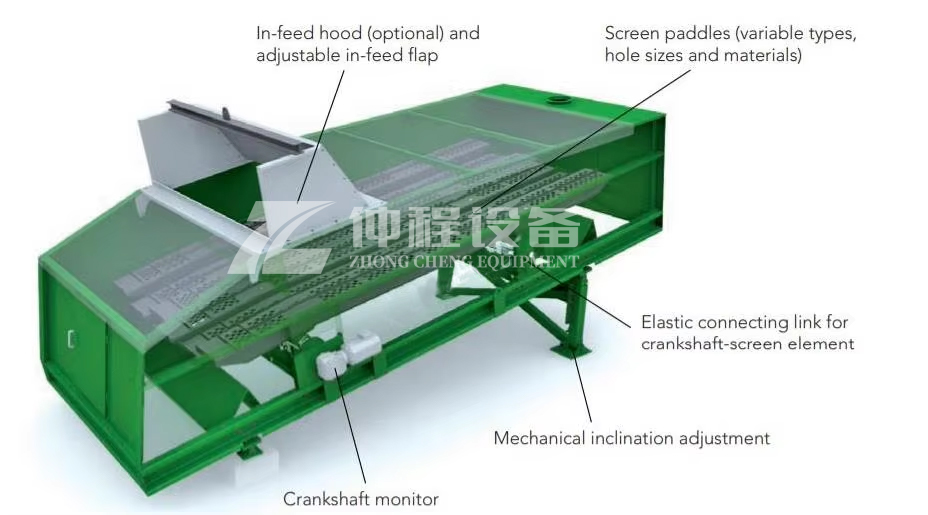

- Vibration Mechanism: Bouncing screens operate by generating vibrations that cause the material on the screen to jump or bounce. This vibration is typically produced by an eccentric shaft or unbalanced motor that creates a shaking motion.

- Material Separation: As the material bounces, smaller particles fall through the screen openings while larger particles remain on top. The angle of the screen and the intensity of the vibration can be adjusted to optimize the separation process for different materials and particle sizes.

- Screen Types: There are various types of screens available, including linear motion screens, circular motion screens, and elliptical motion screens. Each type is designed to handle specific materials and achieve particular outcomes.

Applications:

- Mining: Used to separate ore from waste rock or to grade different sizes of crushed stone.

- Construction: Helps in sorting aggregates and removing fines from sand and gravel.

- Agriculture: Can be used to clean seeds, sort grains, and remove debris from harvested crops.

Recycling: Assists in separating different types of recyclable materials, such as plastics, metals, and paper, from mixed waste streams.

Benefits:

- Efficiency: Bouncing screens can process large volumes of material quickly and efficiently.

- Adjustability: The ability to adjust the screen's settings allows for greater flexibility in handling a variety of materials.

- Durability: Built to withstand heavy use and harsh conditions, making them suitable for industrial environments.

Cost-Effective: Reduces labor costs associated with manual sorting and increases overall productivity.

| Model | Dimension(mm) | power(kw) | Capacity(t/h) |

| 1240 | 1.2m*4m | 5.5kw | 30 |

| 2060 | 2m*6m | 15kw | 150 |

Zhongcheng Machinery Will Be There Whenever Wherever Whatever You Need

You Are Welcome to : phone call, Message, Wechat, Email& Seaching us, etc.

Email:

sales@zchmachinery.com

Whatsapp/Phone:

+8618738194110

hot Products

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

relate news

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-07-16Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...