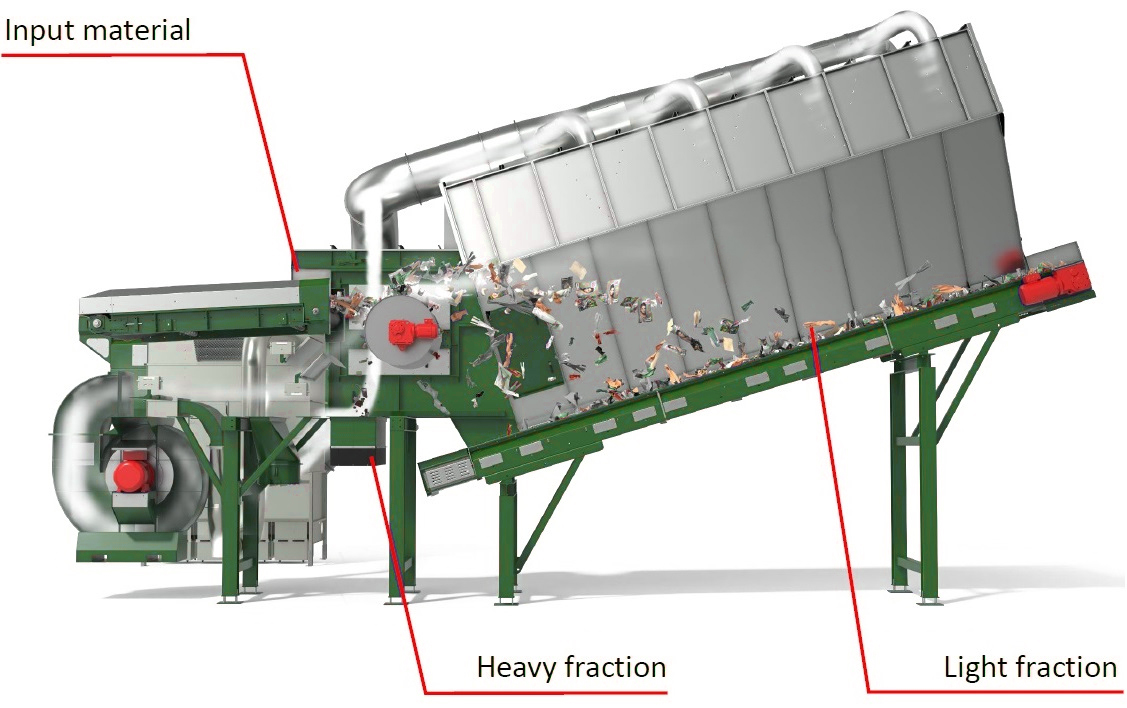

Air Density Separator

The Air Density Separator incorporates three dynamic elements for optimal density separation:

Vibration – Two-Mass natural frequency design liberates materials, and spreads it across the unit effectively

Fluidization – preps the material bed for the air knife by creating turbulence to stratify the materials and liberate the lights trapped beneath heavies

Classification – the air knife provides the final separation, partially by density, partially with aerodynamics, for optimal results

HOW IT WORKS:

1. Vibratory action moves material, with high-density material settling to the bottom of the trough.

2. Fines drop out section (optional) removes smaller particle sizes like broken glass or dirt before reaching air fluidizer.

3. Air fluidizing section blows air through the material and creates turbulence to promote material stratification.

4. Material conveys over the air knife into the air stream. Heavier materials fall through the air stream to the discharge chute.

5. Marginal density material falls on the adjustable landing plate and drops back into discharge chute.

6. Light materials are carried beyond the landing plate and convey to the end of the chamber

7. Ultra-light materials like thin film or paper are carried in the air stream to the product discharge zone.

FEATURES:

Separates heavy product from light product.

Eliminate Environmental hazards associated with water separation.

Easily adjustable to obtain varying degrees of separation.

Adaptable to a wide variety of products.

Jam-resistant. Material flow has zero contact with moving parts.

Low energy demand with low HP motor and proven Two-Mass Design.

Fully isolated design minimizes foundation requirements.

Heavy-duty, built to last construction.

Testing available.

SUCCESSFUL SEPARATING AND CLASSIFYING APPLICATIONS INCLUDE:

C&D materials

RDF fuel

Glass

Commingled materials

Shredded MSW

Shredded auto scrap fluff

Bio-mass fuel

Different models parameter sheets :

| Wind Sifter800 | Wind Sifter1200 | Wind Sifter1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-28Scrap rubber product shredderThe shredder of waste rubber products not only helps to reduce environmental pollution, but also improves the reuse rate of waste rubber, which is one of the im...

-

2024-06-08Five factors influencing the output of a drum screen.The input efficiency and separation efficiency of the drum screen are controlled by the screen hole size, drum screen diameter, rotation speed, baffle type and ...

-

2024-07-16Twin-shaft shredders: ideal for efficient processing of waste and recycling materialsA double-shaft shredder is a mechanical device used to process waste and recycle materials. Its main feature is that it has two rotating shafts with serrated bl...

-

2023-01-13Bag OpenerBag opener or bag opener system is a mechanical device used to automatically open and empty bags containing bulk materials. This system is commonly used in indu...

-

2024-08-06Plastic double shaft shredderOperation:Feeding: The plastic material is fed into the shredder through the infeed system.Shredding: As the material enters the shredding chamber, the rotating...