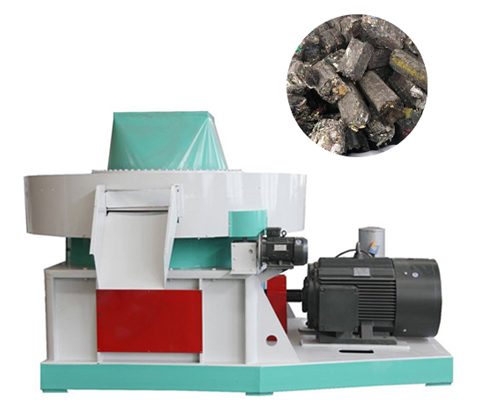

High Capacity Domestic Waste Biomass Briquetting Machine

1).Introduction of Biomass Briquetting Machine

1.This straw briquetting machine adopts a ring-mode structure, which has the characteristics of higher working efficiency and lower failure rate than the traditional flat-die briquetting machine.

2.The biomass briquetting machine uses agricultural and forestry wastes such as corn stalks, wheat straw, cotton stalks, rice straw, rice husks, peanut shells, corn cobs, branches, leaves, sawdust, animal manure, etc. as raw materials and crushes them into biomass briquette fuel, commonly known as ' Straw coal's machinery and equipment.

2).Introduction of Industrial waste briquetting machine

1.Using high-precision involute cylindrical helical gears for direct transmission, the transmission efficiency is as high as over 98%, which is 20-25% higher than the production efficiency of traditional belt-type pellet machines.

2.The transmission gear tooth blank is normalized and heat treated after water forging to improve the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 24mm to enhance the wear resistance and extend the service life of the parts;

3.The hard tooth surface is silently refined the edge grinding process makes the operation quieter and more stable.

4.The bearings used in the particle forming system are all high-quality silent bearings, and a thin oil circulation cooling and lubrication system is added. The bearings have a longer service life and safer operation.

3).Automatic adjustment function of the pressure wheel

The principle of bidirectional rotation of the thrust bearing is used to automatically adjust the pressure angle, so that the material does not squeeze into groups and the machine becomes stuffy, ensuring the stability of the discharging and molding.

4).Application

1.The RDF biomass briquetting machine uses agricultural solid waste such as corn stalks, wheat straw, rice straw, peanut shells, corn cobs, cotton stalks, soybean stalks, chaff, weeds, branches, leaves, sawdust, bark, cloth strips, leather, etc.

2.Materials are used as raw materials, and after crushing, pressurization, densification, and molding, they become small rod-shaped solid briquette fuel. Briquetted fuel is made by extruding wood chips, straw and other raw materials using pressure rollers and ring dies under normal temperature conditions.

3.It is easy to transport and store, and its combustion performance is greatly improved, bringing economic benefits. It is used in compression and densification molding in biomass fuel plants, feed mills, power plants, lumber mills, furniture factories, fertilizer plants, chemical plants, etc.

5). The RDF briquette fuel production line system processes solid waste such as municipal solid waste, mixed waste, and industrial solid waste into low-pollution and high-efficiency garbage-derived fuel RDF with a calorific value of about 5,000kcal/kg.

The RDF produced after processing has high density. It has the characteristics of stable calorific value, easy transportation, easy storage, low secondary pollution and low emission of PCDD/Fs toxic carcinogens.

6). Parameter

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2023-01-12Horizontal Semi-Auto Hydraulic BalerSemi automatic balers are used across the logistics, recycling and manufacturing sectors to process large volumes of waste materials such as cardboard, film, pa...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...

-

2024-10-23Solid waste recycling plantOur company engaged in waste sorting system . We are professional about waste sorting system . We have professional technical team. Professional technical team...