Windshifter Waste Separation Equipment & Supplies

1). Introduction

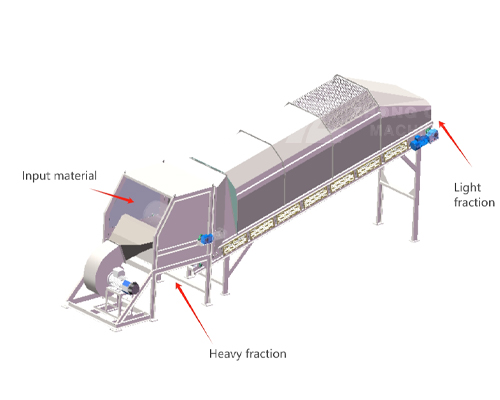

Light material Windshifter is a machine that uses wind power to sort light materials. Its also called Air Drum Separator and Winsifter.

The following is a detailed introduction about it:

2). Working principle:

Based on the principle of aerodynamics, it uses the differences in density and wind resistance characteristics of different materials for sorting. When waste is sent into the air separator, the fan inside the machine will generate a strong wind flow. Light materials such as paper, plastic film, wood chips, etc. are easily blown away by the wind due to their low density and low wind resistance; while heavy materials such as metals, stones, concrete blocks, etc., due to their large weight, are subject to gravity that is much greater than the wind force, and will fall naturally. In this way, the separation of light materials and heavy materials is achieved.

3). Product features:

1. Efficient sorting: It can process a large amount of waste in a short time. One device can process several tons of garbage per hour, which greatly improves the processing efficiency. For example, in the treatment of construction waste, the light materials can be quickly separated to improve the quality of recycled aggregates.

2. Good environmental performance: No water or other chemical reagents are used, avoiding the risk of secondary pollution and meeting environmental protection requirements.

3. Simple structure: The overall structure is relatively simple, mainly composed of a box, a rack, an air supply system, a return air system, a conveying system, etc., with low maintenance costs and suitable for long-term continuous work.

4. Strong applicability: It is not only suitable for the treatment of urban solid waste, but also can be used in agriculture, forestry and other fields. For example, in agriculture, light straw can be separated from heavy grains, and in forestry, leaves and other light organic matter can be separated.

5. Flexible operation: The wind speed can usually be adjusted infinitely to meet the sorting needs of materials with different properties, including high-humidity materials.

4). Application scenarios:

1. Construction waste treatment: Construction waste often contains a large amount of light materials such as plastics, paper, and cloth, which will affect the quality of recycled aggregates. The light material air separator can separate it from the construction waste, which is convenient for the subsequent recycling of light materials and improves the purity of recycled aggregates.

2. Domestic waste treatment: It is used to separate recyclable light materials such as plastics, paper, and wood blocks in domestic waste to achieve waste reduction and resource utilization.

3. Renovation waste treatment: Renovation waste has complex components and contains a large amount of light materials such as plastic film, paper, etc. The use of air separators can effectively remove these light materials and improve the treatment efficiency and resource recycling rate of renovation waste.

5). Technology development trends:

1. Intelligence: In the future, it may combine technologies such as artificial intelligence and big data to achieve more intelligent control and operation, and automatically adjust the sorting parameters according to the composition and characteristics of the garbage to further improve the sorting efficiency and accuracy.

2. Collaborative operation: Combined with other sorting technologies such as magnetic separation and screening, a comprehensive sorting system is formed to make up for its own shortcomings in sorting materials with similar density or irregular shapes, and achieve better sorting effects.

3. Large-scale and small-scale: According to different application scenarios and processing requirements, it develops in two directions: large-scale and small-scale. Large-scale equipment can be used in large-scale garbage treatment plants or construction waste treatment bases to improve processing capacity; small-scale equipment is suitable for small garbage transfer stations or community garbage treatment points.

6).Parameter

| Windshifter800 | Windshifter1200 | Windshifter1600 | |

| Feeding Belt Width | 800mm | 1200mm | 1600mm |

| Air volume | 8000-19000 m³/h | 12000-29000 m³/h | 15000-35000 m³/h |

| Full pressure | 2500Pa | 2500Pa | 2500Pa |

| Power | 38kw | 42kw | 55kw |

| Throughput | 20-30 m³/h | 30-50 m³/h | 50-70 m³/h |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2024-06-06Drum Screen For Composting PlantDrum screen, also known as a rotary drum screen or trommel screen, is an essential piece of equipment used in composting plants for the separation of compost ma...

-

2024-06-09Advantages of Using Drum Screening Machines in Waste ManagementUnderstanding the working principle of drum screening machines is essential to appreciate their efficiency and effectiveness in waste management. Operation and ...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2023-01-12Vibrating ScreenVibrating screen is a mechanical device used to separate materials into different sizes and grades by vibrating them through a mesh or screen. This equipment is...