Horizontal baler: an industrial tool for efficient compression and material management

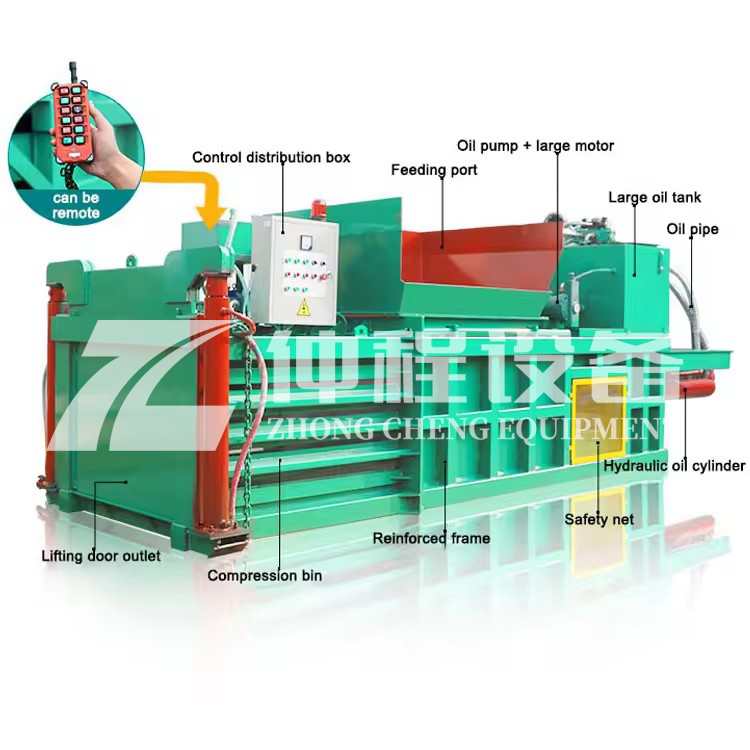

Introduction to Horizontal Baling Machines

A horizontal baling machine, also known as a horizontal baler or horizontal press, is an industrial equipment designed to compress various materials into dense, manageable bales. These machines are widely used in recycling centers, waste management facilities, and manufacturing plants to process and prepare materials for transportation or storage.

Working Principle

Material Feeding: The process begins with the feeding of loose materials into the machine. Depending on the design, this can be done manually or through an automated feeding system.

Compression: Once the material is inside the machine, it is compressed using hydraulic rams. The hydraulic system applies high pressure to reduce the volume of the material, making it more compact and easier to handle.

Bale Formation: As the material is compressed, it is pushed into a bale chamber where it forms a dense bale. The size and shape of the bale can vary depending on the machine's specifications and the type of material being processed.

Tying and Ejection: After the bale reaches the desired density, it is tied with wire, string, or straps to maintain its shape. The completed bale is then ejected from the machine, either manually or automatically, to make room for the next cycle.

Application Industries

Recycling Centers: Horizontal baling machines are essential in recycling facilities for processing paper, cardboard, plastics, metals, and other recyclable materials. They help in reducing the volume of waste and preparing it for efficient transportation to recycling plants.

Waste Management: In waste management, these machines are used to compress non-hazardous waste such as municipal solid waste, agricultural waste, and industrial waste. This helps in reducing the amount of space required for storage and disposal.

Manufacturing Plants: In manufacturing, horizontal baling machines are used to manage production waste, such as scrap metal, plastic scraps, and packaging materials. By compressing these materials, manufacturers can reduce waste handling costs and improve their environmental sustainability.

Agriculture: In the agricultural sector, these machines are used to bale hay, straw, and other crop residues. This makes it easier to store and transport these materials, which can be used for animal feed or biofuel production.

Textile Industry: Horizontal baling machines are also used in the textile industry to compress fabric scraps, yarn, and other textile waste. This helps in managing waste efficiently and reducing the environmental impact of textile production.

Benefits

- Volume Reduction: Significantly reduces the volume of materials, making them easier to handle, store, and transport.

- Cost Savings: Reduces transportation and storage costs by compressing materials into smaller, denser bales.

- Environmental Impact: Helps in managing waste more sustainably, reducing landfill usage and promoting recycling.

Efficiency: Automated processes increase productivity and reduce labor requirements.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2025-04-21Compact Copper Cable Granulator MachineThe compact copper cable granulator machine is a device used to recycle waste wires and cables. It separates the copper wire from the plastic sheath by crushing...