Flip Flow Screen

Flip Flow Screen

The solution for screening difficult material

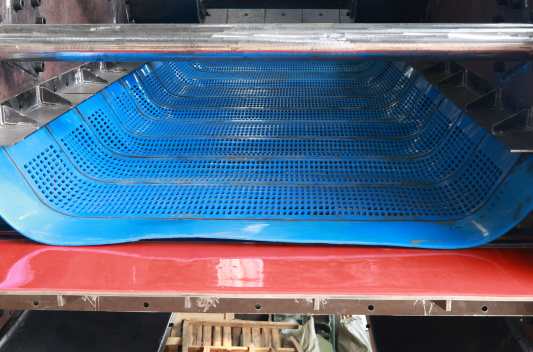

The Flip Flow screen is composed of a screening surface formed

by elastic meshes. The equipment generates relative movement

in both sieving frames, creating a “trampoline effect” in the meshes

achieving high efficiency. The modular and compact construction

of Flip-Flow technology ensures wide acceptance for many different

applications.

Robust and Efficient Equipment

In the design of the Flip Flow Screen, even the last detail has been thought in order to be the final sieving solution with the best quality

The design of the sieving area provides optimum distribution

and recirculation of the material through the cascade effect

that is achieved in the material path through the sieving mats.

The base is agitated by means of an axis. The vibration is

transmitted to the dynamic structure through push rubbers.

Maintenance

The elastic mesh model is characterized by optimal sieving with low maintenance.

Flip-Flow sieve meshes are fixed without screws and have no edges that could cause difficulties. This means that the meshes can be changed quickly. Stationary or co-vibrant coverage can be opened without using tools, ensuring quick and simple access to sieving meshes.

Parameters sheet :

| Nominal Aperture Size (mm) of Screening Elements | Stroke (mm) | Speed (rpm) | G Index (target) Loaded | |

| Scalping | >75 | 12.0 - 10.5 | 750 - 800 | 3.8 |

| Ballast | 75 to 32 | 10.0 - 8.5 | 850 - 900 | 4.0 |

| Aggregates | 25.4 to 6.7 | 9.0 - 8.0 | 900 - 950 | 4.1 |

| Fines Separation | <6.7 | 8.0 - 7.0 | 950 - 1000 | 4.0 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2023-01-12Waste FeederWaste feeder was specially designed to optimize municipal solid waste sorting systems. The Drum Feeder ensures that your sorting system, baler or shredder has a...

-

2024-06-11Optimize Your Waste Management Today with Our Advanced Drum ScreensUnderstanding the Mechanism and Optimization of Drum Screens for Waste Management

-

2024-08-22Medical waste shredderWorking Principle:Feeding Mechanism: Medical waste is fed into the shredder through a hopper or chute. The feeding mechanism ensures that the waste is introduce...