Comprehensive analysis of horizontal baler

Working Principle of Horizontal Baling Machine

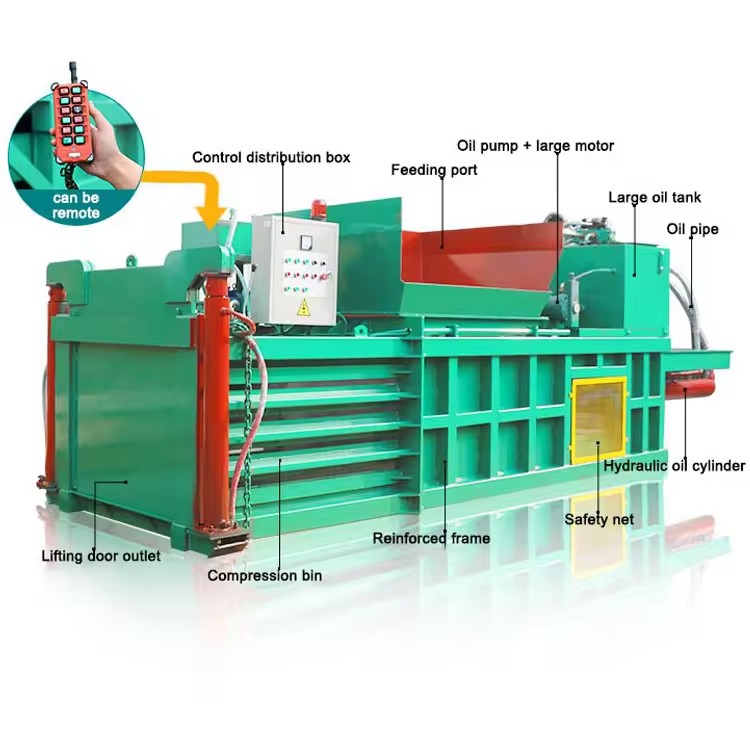

A horizontal baling machine, also known as a horizontal baler, compresses recyclable materials into compact bales. The working principle involves feeding the material to be recycled into the machine's chamber. Inside, hydraulic rams or pistons apply pressure to compress the waste material. Once compressed to the desired density, the baling wire or strap is automatically wrapped around the material to maintain its shape and integrity. Afterward, the bale is ejected from the machine.

Applications and Uses

Horizontal balers are widely used for compressing various types of recyclables, including but not limited to paper, cardboard, plastics, textiles, and aluminum cans. They are essential in waste management, recycling centers, and industries that generate large volumes of recyclable waste.

Operation

Operating a horizontal baling machine typically requires minimal training. Operators need to ensure the machine is properly set up, load the material to be baled, start the compression cycle, and monitor the process to make sure everything runs smoothly. Safety measures must always be adhered to, such as keeping hands away from moving parts and ensuring the machine is turned off when performing maintenance.

Industries

These machines find application across numerous industries, such as:

- Recycling facilities

- Manufacturing plants

- Retail and distribution centers

- Paper mills

Waste processing companies

Advantages

The advantages of using a horizontal baling machine include:

- Efficiency: High throughput rates allow for quick processing of large amounts of material.

- Space Saving: Compact bales save space during storage and transport.

- Cost-effective: Reduces transportation costs due to higher density of baled materials.

- Environmental Benefit: Promotes recycling and reduces landfill usage.

Automation: Many models come with automated features that reduce labor requirements.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Double-Shaft ShredderThe Double-shaft shredder is a widely used industrial shredder that efficiently processes various mixed waste materials, such as construction waste, industrial ...

-

2024-08-07Efficient Material Separation with Bounce ScreensThe ballistic separator is an important equipment with separation function designed for the sorting of inorganic particles in the coarsely crushed waste.

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-18Metal BalerMetal baler, specifically a hydraulic metal baler, is a machine designed to compress scrap metal into dense, manageable bales. This equipment is widely used in ...

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...