How Does Biomass RDF Briquetting Machine Turn Waste into Treasure

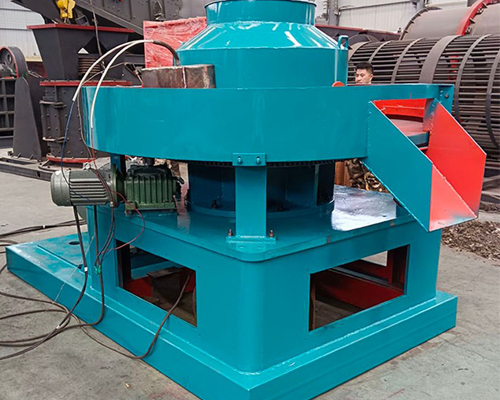

1). Biomass RDF (Refuse Derived Fuel) Briquetting Machines a kind of equipment specially used to convert waste into fuel rods. This technology not only helps in waste management, but also produces environmentally friendly energy products that can replace traditional fossil fuels. The following is a detailed introduction to the working principle, advantages and application areas of Biomass RDF Briquetting Machine:

2). Working principle

1. Raw material preparation: First, the collected waste needs to be sorted and pre-processed to remove the parts that are not suitable for processing into fuel, such as metal, glass, etc. Then the remaining organic matter, paper, plastic and other combustible materials are crushed to a certain size.

2. Mixing and conditioning: The crushed raw materials are mixed in a certain proportion, and an appropriate amount of water or other additives are added to improve their physical properties, such as improving adhesion and fluidity, to ensure the smoothness of the subsequent molding process.

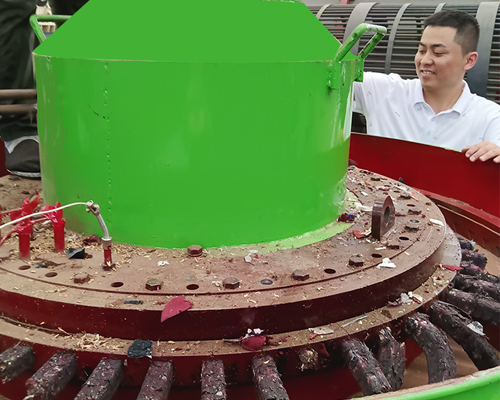

3. Molding compression: The mixed materials are pressed into the required shape of fuel briquette using the pressure system inside the briquette making machine. In this process, high temperature and high pressure conditions help to enhance the density and stability of the fuel briquette.

4. Drying and curing: The molded fuel rods need to be dried to reduce the moisture content, increase combustion efficiency and reduce the risk of mildew during storage.

5. Packaging and storage: Finally, the dried fuel briquette will be packaged and stored in the warehouse for sale or direct use.

3). Advantages

1. Resource recycling: It effectively solves the problem of urban domestic waste and industrial waste treatment and realizes the reuse of resources.

2. Environmentally friendly: Compared with traditional fossil fuels, Biomass RDF Briquetting Machine produce lower carbon dioxide emissions when burned, which is beneficial to environmental protection.

3. High cost-effectiveness: By recycling waste to make fuel, the cost of energy production can be significantly reduced.

4. Strong flexibility: It can adjust the raw material formula and finished product specifications according to different needs, and has a wide range of applications.

4). Application areas

1. Industrial boilers: Boilers in many industrial facilities can use Biomass RDF Briquetting Machine as an energy source, especially those industries with high environmental protection requirements.

2. Power plants: In some countries and regions, RDF has been used as an important renewable energy source for power generation.

5). In summary, the Biomass RDF Briquetting Machine factory not only provides an effective solution to the problem of environmental pollution, but also contributes to the development of green energy.

Parameter

Model | Power(KW) | Capacity(T/H) | Mold quantity | Roll quantity | Over dimension(MM) |

9JK-2600 | 75 | 1-2 | 52 | 2 | 2647*2100*1900 |

9JK-3500 | 110 | 2-3 | 72 | 2 | 3250*2600*2000 |

9JK-4500 | 132 | 3-4 | 88 | 2 | 3350*2800*2200 |

9JK-5000 | 160 | 4-5 | 100 | 2 | 3000*2300*2000 |

9JK-5500 | 160 | 4-5 | 102 | 2 | 3000*2400*2000 |

9JK-6500 | 200 | 4-5 | 120 | 3 | 4400*2970*2495 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-06-07Zhongcheng Air Drum Separator in MSWAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2024-08-20A rubber double shaft shredderExamples of Specific Models:GDB Series Biomass Shredder: Although primarily designed for biomass materials, this model can also be configured to handle various ...

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...