Efficient Separators: Unmasking Bounce Screen Technology in Modern Industry

Descriptions of ballistic separator/Bouncing sieve/Bouncing screen

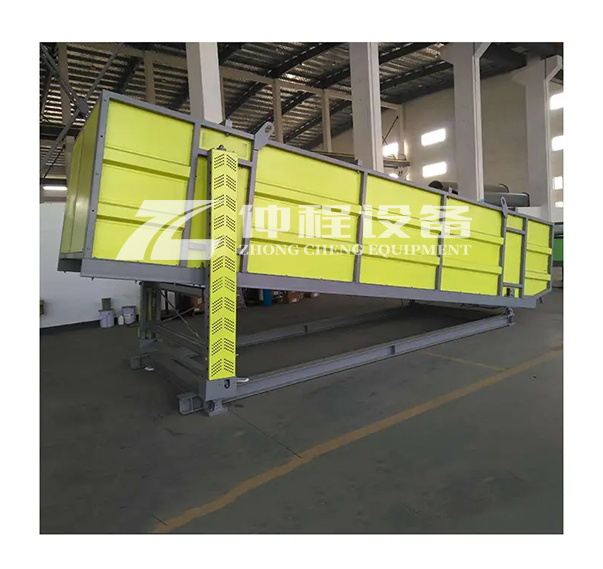

Bounce sorting screen is a device that sorts materials based on the size, density, and shape of different components. It is an ideal equipment for processing and sorting household waste, stale waste,decoration waste,industrial waste, paper recycling, and other industries. Bounce sorting screen drives the screen plate up and down to move back and forth through an eccentric shaft, causing the household waste on the screen plate to be shaken and scattered into heavy,rolling 3D material parts (such as plastic bottles, wood, cans, etc.), light, flat 2D material parts (film, paper, cardboard, old clothes), and undersized material parts (sand, food residue), which facilitates the subsequent processing.

Working Principle

A bouncing screen (also known as a bouncing screening machine or a vibrating screen) is a device used for industrial material separation. It operates by causing the material to move on the screen surface through vibration and separating it based on particle size.

Working Principle

The main mechanism of a bouncing screen relies on the excitation force generated by a vibrating motor, which causes the screen box to vibrate and in turn makes the material on the screen perform a tossing motion or linear movement. When the material enters the screen surface, particles smaller than the screen aperture fall through, while larger particles remain on the screen surface and continue to move forward until they are discharged from the outlet. This equipment can typically adjust the vibration frequency and amplitude to suit the needs of different material properties.

![]()

Application Industries

Bouncing screens are widely used in various fields, including but not limited to:

- Mining Industry: Used for grading and screening ores.

- Chemical Industry: Used for the screening and separation of chemical raw materials.

- Food Processing: Used for the screening of food ingredients such as grains and tea.

Construction Materials: Used for the screening of building materials like sand, gravel, and cement.

Advantages

- Efficiency: Can quickly complete material screening, improving production efficiency.

- Flexibility: Can adjust the number of screen layers and the size of the screen apertures according to requirements.

- Durability: Rugged design suitable for long-term continuous operation.

Ease of Maintenance: Relatively simple structure that facilitates daily maintenance and repair.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2023-01-18RDF Making MachineRDF (Refuse Derived Fuel) making machine is a specialized equipment used in waste management and energy recovery processes. Its primary function is to convert v...

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-08-07Tire double shaft shredderOperation:Feeding: Whole or pre-cut tires are fed into the shredder through an inlet hopper.Shredding: As the tires enter the shredding chamber, the rotating cu...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...