Bounce screen: Efficient industrial screening solution

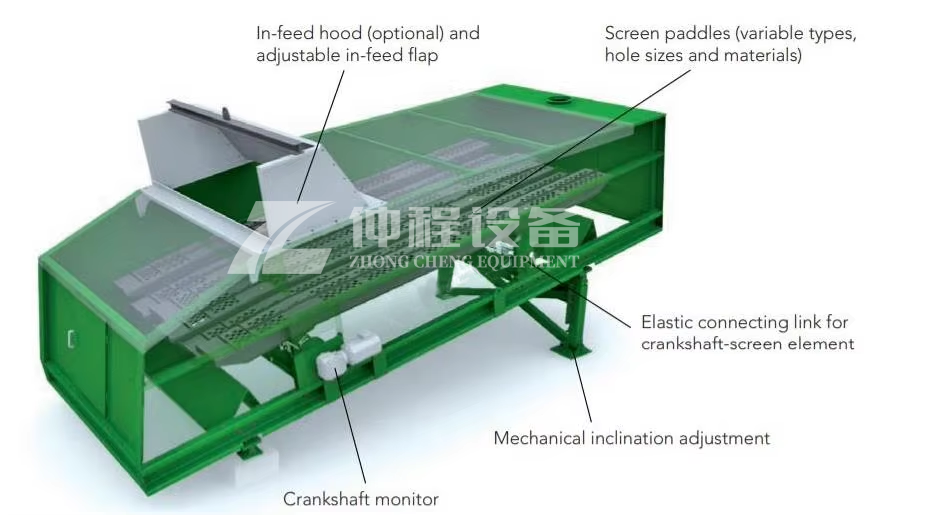

Working Principle

A bouncing screen operates by utilizing an inclined screening surface that vibrates or bounces. As material is fed into the screen, the vibration or bouncing action causes the material to move forward along the screen. Smaller particles fall through the screen openings, while larger particles that do not fit through the openings are discharged at the end of the screen. This process effectively separates materials based on particle size.

Advantages

- Efficiency: The continuous motion helps prevent clogging of the screen apertures, which increases the throughput and efficiency of the screening operation.

- Durability: The design often includes wear-resistant components and materials to withstand the harsh conditions of industrial use.

- Versatility: By adjusting the mesh size and shape, the bouncing screen can adapt to different types of materials and application requirements.

- Ease of Maintenance: With a relatively simple structure, maintenance and cleaning are straightforward, reducing downtime for service.

Energy Efficiency: Compared to some other types of screening equipment, bouncing screens may consume less energy due to their operational mechanics.

Industries Where Used

Bouncing screens find applications across a wide range of sectors:

- Mining Industry: For the initial screening of ores.

- Agriculture: For sorting grains, seeds, and other agricultural products.

- Chemical Industry: For the classification of chemicals.

Food Processing: For screening food ingredients to ensure product quality.

Main Functions

"The main functions of a bouncing screen include the separation of materials by size, allowing smaller particles to pass through the screen while retaining larger particles. This equipment plays a critical role in industrial processes where material classification is necessary for quality control and preparation. Its key features enable it to handle various materials efficiently, making it indispensable in sectors such as mining, agriculture, chemical processing, and food production. The ability to adjust settings for different applications further enhances its utility across diverse industries."

| Model | Dimension(mm) | power(kw) | Capacity(t/h) |

| 1240 | 1.2m*4m | 5.5kw | 30 |

| 2060 | 2m*6m | 15kw | 150 |

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2025-03-03Mini Copper Wire GranulatorThe copper wire granulator machine is a device specially used to process waste wires and cables. Its main function is to separate the copper and plastic in the ...

-

2023-01-11Ballistic SeparatorBallistic separators are a crucial component in modern recycling and waste management systems, contributing to more efficient resource recovery and environmenta...

-

2023-01-11Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.

-

2024-04-13Vibrating FeederA vibrating feeder is a mechanical device used to convey materials, typically in bulk, from one location to another in a controlled manner. This equipment is co...

-

2024-05-18Mobile Jaw Crusher PlantMobile jaw crushing station is a novel rock crushing equipment, also known as mobile crushing station. The purpose of its design concept is to stand from the cu...