How a Trommel Screen Works

People use screening equipment to separate different material grades such as soil, gravel, mulch, and sand. These machines work great when working with dry material, even if bits and pieces are large. However, a notable weakness is a difficulty that traditional screeners have with wet materials such as moist soil, wet sand, and compost. These substances tend to clump together when they are wet, which reduces the machine’s efficiency. In addition, moist material can clog up the machine and stick to the screen. This clog can be difficult to dislodge and will cost a lot of time. Fortunately, trommel screen sifters are available to make these tasks much more straightforward

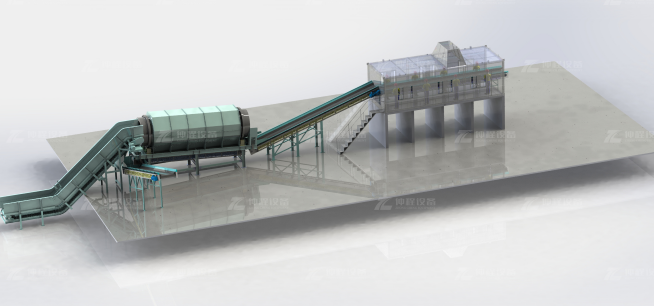

A trommel is a screen curved into a cylinder. The machine spins the cylindrical screen to sort through the material as you feed it through. During this process, the wet material tumbles around. Air gets added, and the soil, mulch, or sand becomes lighter and drier. The tumbling action also allows maximum contact time with the screen so that the fine material gets through quickly. As a result, a trommel screen can rapidly sort through dry substances, even though they specifically designed these trommels for wet material.

These sifters come in different sizes, but they are generally portable enough to be moved by truck. This portability is convenient if you need to screen soil or mulch in more than one area of a homestead or if you need to move the machine to a different location entirely. Due to the materials that trommel screens specialize in, they are particularly popular with landscapers and excavating contractors. When things need to get done quickly, you cannot depend on your material being dry enough for a standard screening machine. Every handyperson knows the importance of bringing the right tool for the job. After all, the bigger the job, the more important the tool.

Cities can often find a lot of uses for screening machines. Trommel machines are particularly useful because they can handle various tasks with speed. A quality screener pays for itself quickly when several tasks are at hand. They are a beast that can take on a lot of work, but be sure not to overfill the machine. With a trommel, additional material beyond the designed capacity will only slow things down. The screen’s surface area is the limiting factor, so clogging the center of the rotary with more dirt or mulch will not accomplish anything. These machines are of top-notch quality, so it is important to remember that they should be allowed to work at their set pace. Even if there is a lot of labor to be done, the trommel will cut through it at a healthy speed, so let it run its course.

| Model | Length Range | Segment No. | Aperture Size | Power (Kw) | Inclined Angle | Max. Material Size | Rotating Speed(rpm) |

| ZCφ600 | 2-4m | 1-2 | ≤30mm | 2.2-3 | 0-7° | 60mm | 12-18 |

| ZCφ800 | 2-5m | 1-3 | ≤50mm | 3-5.5 | 0-7° | 100mm | 12-18 |

| ZCφ1000 | 2-6m | 1-4 | ≤100mm | 4-11 | 0-7° | 150mm | 10-18 |

| ZCφ1200 | 3-8m | 1-4 | ≤150mm | 5.5-18.5 | 0-7° | 200mm | 9-15 |

| ZCφ1500 | 3-10m | 1-5 | ≤200mm | 7.5-22 | 0-7° | 250mm | 9-15 |

| ZCφ1800 | 4-12m | 1-5 | ≤220mm | 7.5-22 | 0-7° | 270mm | 8-15 |

| ZCφ2000 | 5-15m | 1-5 | ≤250mm | 11-30 | 0-7° | 300mm | 8-12 |

| ZCφ2500 | 5-18m | 1-6 | ≤300mm | 11-30 | 0-7° | 350mm | 8-12 |

customized according to your requirements

In conclusion, trommel screens play a crucial role in the processing and sorting of materials across numerous industries. Their robust design, combined with efficient screening capabilities, makes them an invaluable tool in modern material handling and recycling processes.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-06-05Can the Angle of the Ballistic Separator Be Adjusted?Ballistic separator is a type of mechanical sorting device used primarily in the recycling industry to separate materials based on their physical properties. It...

-

2024-07-09Recycling Balers-Safe,Easy-To-Use and affordableThe operating principle of a strapping machine primarily involves the following steps:1.Item Positioning:Firstly, the item to be strapped must be placed accurat...

-

2023-01-12Apron FeedersApron Feeder is a conveyor manufactured from steel plates driven by steel chains wearing on steel surfaces. They are a robust design manufactured for durability...

-

2024-06-20Wind Separator Technology for Lightweight Materials in Urban Solid Wastewind separator, also known as air separation, is a sophisticated and efficient method of sorting that utilizes air as the separating medium.

-

2023-01-12Impact CrusherImpact crusher is a type of machine designed to reduce large rocks, ores, and other hard materials into smaller, more manageable pieces. This equipment is widel...