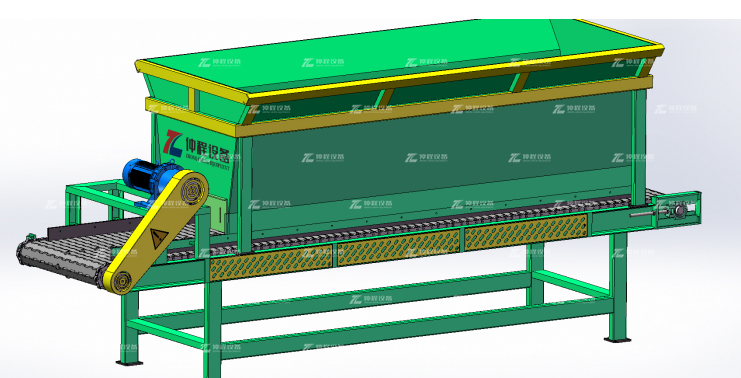

Chain Plate Feeder

What is a Chain Plate Feeder?

A chain plate feeder is a type of material handling equipment that uses a series

of connected plates, driven by a chain, to transport bulk materials. These feeders

are designed to handle heavy loads and provide consistent feed rates, making

them ideal for industries that require reliable material transport.

The sleeve roller chain drives the sprocket cyclic reciprocating motion provides

traction power, and the metal plate is used as the carrier to transport materials.

It has strong impact resistance and is suitable for all kinds of complex garbage.

Key Features

Chain plate feeders are known for their robust construction and efficient operation.

Key features include:

Heavy-Duty Construction: Built from high-strength materials to withstand heavy

loads and harsh operating conditions.

Consistent Feed Rate: Designed to deliver a steady and controlled flow of materials,

ensuring uniform feed rates.

Customizable Design: Available in various sizes and configurations to meet

specific application requirements.

Low Maintenance: Engineered for durability and minimal maintenance, reducing

operational downtime.

Versatility: Suitable for transporting a wide range of materials, including abrasive

and high-temperature substances.

Applications of Chain Plate Feeders

Chain plate feeders are used in various industries due to their reliability and efficiency.

Common applications include:

Mining: Transporting ore, coal, and other mined materials from extraction sites to processing facilities.

Construction: Handling bulk materials such as sand, gravel, and cement in construction projects.

Recycling: Feeding recyclable materials, including metals, plastics, and glass, into processing systems.

Power Generation: Delivering coal, biomass, and other fuels to boilers and furnaces in power plants.

Manufacturing: Transporting raw materials and components in various manufacturing processes.

Benefits of Using Chain Plate Feeders

Implementing chain plate feeders in material handling processes offers numerous benefits:

Enhanced Efficiency: Streamlines material transport, reducing handling time and labor costs.

Increased Reliability: Provides consistent and reliable operation, minimizing disruptions in the workflow.

Cost Savings: Reduces maintenance and operational costs due to durable

construction and low maintenance requirements.

Improved Safety: Reduces the need for manual handling of heavy materials,

enhancing workplace safety.

Environmental Impact: Efficient material handling reduces energy consumption

and waste, supporting sustainability efforts.

Our Commitment to Quality

We are dedicated to providing high-quality chain plate feeders that meet the

diverse needs of our clients. Our feeders are designed with precision engineering

and built to last. We offer comprehensive support, from initial consultation and

design to installation and maintenance.

Explore our range of chain plate feeders and discover how they can enhance your

material handling operations. Contact us today to learn more about our products and services.

-

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote

Trommel screenTrommel screen, also known as drum screens, are widely used in various industries for sorting and separating materials.Get Quote -

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote

Crop straw double shaft shreddApplications:Biomass Energy Production: Shredded straw can be used as a feedstock for bioenergy plants to produce electricity or heat.Livestock Feed: Reduced-si...Get Quote -

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

Zhongcheng Air Drum SeparatorAir drum separators effectively separate lightweight materials (e.g., plastics, paper) from heavier materials (e.g., metals, glass). This high efficiency is cru...Get Quote

-

2024-05-18Jaw CrusherThe working principle of jaw crusher Although the jaw crusher has various structural types, its working principle is the same, that is, the material is crushed ...

-

2024-08-05Hot-sell Coconut Shredderworking principleCoconut shell shredder usually uses the force generated by cone and spiral to evenly squeeze the coconut meat in the grinding chamber between t...

-

2024-08-12The Advantages of Horizontal Baling TechnologyA horizontal baler, also known as a horizontal baling machine, is a piece of equipment used for compressing materials and wrapping them into bales. This process...

-

2024-07-16Drum screen garbage processing machine for msw recyclingManaging municipal solid waste (MSW) efficiently is crucial for urban areas. Drum screen garbage processing machines are a game-changer in this field. They ensu...

-

2023-01-12WindshifterWindshifter (Air Drum Separator ) is the ideal solution for separating all kind of waste types into two fractions, heavy and light. The robust construction and ...